SolidWorks and CATIA are prominent CAD software with a wide range of applications, both made by Dassault Systemes.

But, they target different industries, and there are different job opportunities for CATIA and SolidWorks CAD modelers. So, this article will compare SolidWorks and CATIA thoroughly to help you understand which is best for you.

In a nutshell, SolidWorks is more user-friendly than CATIA and easier to learn. SolidWorks is the better CAD software to begin your modeling adventures if you’re entry-level.

Designing parts is also faster with SolidWorks than with CATIA. Therefore, part manufacturers prefer SolidWorks over CATIA.

On the other hand, CATIA is more machine-friendly than SolidWorks. So, CATIA is better than SolidWorks for modeling and simulating large designs.

Also, CATIA has more powerful surface design features and can manage very large designs. Therefore, industries that make complex machines, like cars and aircraft, prefer CATIA over SolidWorks.

CATIA vs SolidWorks: A Summary

Engineers and manufacturers widely use both software. CATIA and SolidWorks have exceptional capabilities that separate them from ordinary CAD software.

Both SolidWorks and CATIA can do 3D modeling, reverse engineering, electronics design, material stress simulation, input-output simulation, fluid dynamics simulation, CAM tool paths, mechatronic machine design, and more.

But, here is a short glance at their differences.

SolidWorks Advantages Over CATIA

- More user-friendly.

- Easier to learn.

- Easier to use.

- Small designs are faster with SolidWorks.

- Companies that make parts and average-size components require SolidWorks skills.

- SolidWorks is cheaper than CATIA.

- SolidWorks costs very little for students, artists, and startups.

CATIA Advantages Over SolidWorks

- More capable in simulating large designs.

- Better surface design capabilities.

- Project management is better for large and complex designs.

- Companies that make complex machines like cars and aircraft may require CATIA knowledge.

We’ll compare CATIA and SolidWorks in detail next.

UI: SolidWorks vs CATIA

Opening CATIA (the full version) exposes you to more than a hundred design environments. It’s overwhelming and very specialized. You’ll need to understand the various design environments to access different tools.

For example, you should go to “Mechanical Design” and then “2D Layout for 3D design” to access tools for drawing 2D geometries.

While CATIA flaunts its tremendous specialized functions right from the beginning, SolidWorks opens with a much simpler user interface, showing fewer tools.

But don’t let this simplicity fool you! SolidWorks has many add-ons for extension, while CATIA gathers many functions in its design environments from the beginning.

For example, CATIA has a “Machining” environment to generate g-codes for CNCs, while SolidWorks has a SolidCAM add-on. Both of these have advanced machining tools.

CATIA vs SolidWorks: Which Is More User-Friendly?

SolidWorks is much more user-friendly than CATIA. However, this gives CATIA a surprising advantage over SolidWorks.

SolidWorks is very user-friendly and intuitive. It caters to the user with visual interfaces (much more than CATIA).

On the other hand, CATIA is deliberately designed to prioritize the computer flow over the user’s experience. This helps CATIA optimize computer modeling and simulations in large projects. We’ll explain more about this later.

Case in point, let’s say you want to make a 3D shape from an image you like. You can import the image into SolidWorks, get its sketch with just one click, and then extrude it. You can do this with little training.

However, good luck finding how to sketch the image in CATIA on your own! I’m sure CATIA can do it, but you’ll need a strong command of CATIA to design with it.

Learning Curve: SolidWorks vs CATIA

Learning SolidWorks is easier than CATIA. Beginners with no prior CAD skills find CATIA stern, inflexible, and tiring.

Is CATIA Difficult to Learn?

CATIA is more difficult to learn than most CAD software, since it’s neither intuitive nor user-friendly. CATIA is also harder to use once you’ve learned it, and CATIA skills are easier to forget than most other CAD software.

Understanding CATIA requires a top-down thought process, while SolidWorks welcomes bottom-up learning. Let’s investigate what this means for the user.

You can learn SolidWorks by beginning with a simple example. Then, you can expand your knowledge until you become an expert.

However, learning CATIA involves understanding various CAD aspects and program rules. But, a beginner can’t vividly see how these aspects fit together through CATIA’s logic – it’s difficult for beginners to understand the math behind the scenes. But, CATIA demands the user to set many variables and know where to find them.

Plus, if you come back to SolidWorks after abandoning it for a year, you can practice a little and get back on track. However, if you leave CATIA for a year, you’ll need extensive training to regain your skills.

How Do You Learn CATIA?

For the above reasons, many CATIA experts have started with other CAD programs like AutoCAD and SolidWorks before learning CATIA. This gives the CATIA learner a leg up since the 3D design thought process remains similar to SolidWorks.

For example, let’s say you’ve learned how to make a cube in SolidWorks: you start by drawing a 2D square, and then extrude it into a cube. Now if you’re learning CATIA, although it’s a bit more difficult to find the appropriate tools, you can use the same thought process.

In CATIA you’ll learn to navigate to its 2D environment to draw the same square. Then you’ll find its extruding function, which CATIA calls “padding.” Having CAD skills before learning CATIA helps to adjust to its top-down approach.

Ease of Use: SolidWorks vs CATIA

We’ve already mentioned that SolidWorks is more user-friendly and easier to learn than CATIA. SolidWorks is also easier to use than CATIA even if you are an expert in both programs.

For example, both software can do motion analysis. If you put together a bicycle from many assemblies, they will show how the bike responds to turning the pedals.

However, SolidWorks’ motion study is easier to perform. You’ll need more commands and effort in CATIA to study the motion.

For another example, let’s say you’ve made several mistakes in your design. When you test your design with SolidWorks, it’ll show you something, even if it’s awkward. This helps you to find your mistakes.

However, CATIA won’t return anything if you have design errors. It will just give you an error that says the mechanism can’t be simulated.

Therefore, spending one hour with CATIA can be more mentally draining than an hour with SolidWorks. Plus, it takes longer to implement the same design in CATIA.

Then, Why do people use CATIA?

CATIA is excellent software for large-scale designs. Although CATIA is not user-friendly, it’s machine-friendly so that the computer can handle large-scale modeling and simulation. Also, CATIA has exceptional surface modeling abilities. We’ll explain these shortly.

Tools and Capabilities

CATIA and SolidWorks are tremendously capable software. CATIA used to have many more tools and capabilities, but SolidWorks’ add-ons have caught up in the past few years.

CATIA has various modeling, analysis, and simulation features in its environments, while SolidWorks has many add-ons to bring these features to SolidWorks too.

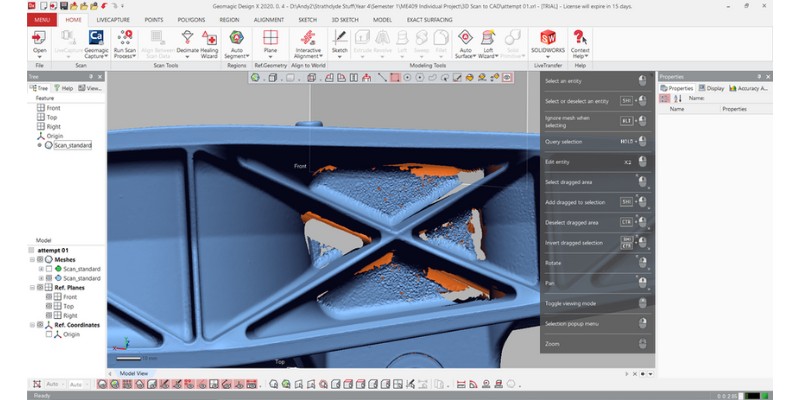

For example, CATIA has fantastic features for reverse engineering, yet SolidWorks’ Geomagic add-on can do similar things. You can import large mesh or STL files in Geomagic, scan to 3D, and do “point cloud” analysis. You could only do these things in CATIA a decade ago.

- Therefore, both software can model 3D parts and designs, connect assemblies, simulate motions according to physics laws, do various simulations, and do CFD and material analysis.

- You can design different parts, and both software can put the parts together to make a machine and simulate how it runs.

- Both software can manage several designers. They can break the projects, and synthesize the works of various team members.

- Both software can model electrical and mechanical components. So, you can make machinery with electrical and mechanical parts with them.

But, CATIA and SolidWorks have different capabilities and target different industries. We’ll reveal the different capabilities, next.

Differences Between SolidWorks and CATIA Capabilities

So far, we’ve seen how SolidWorks is easier than CATIA. However, CATIA has some tricks up its sleeve.

What can CATIA do that SolidWorks can’t?

CATIA has more powerful surface designing abilities than SolidWorks. CATIA can simulate very large projects without crashing, while SolidWorks can’t. CATIA can manage lots of designers in a large modeling project and connect their designs, while SolidWorks can’t manage large projects as smoothly.

We’ll elaborate on these points separately.

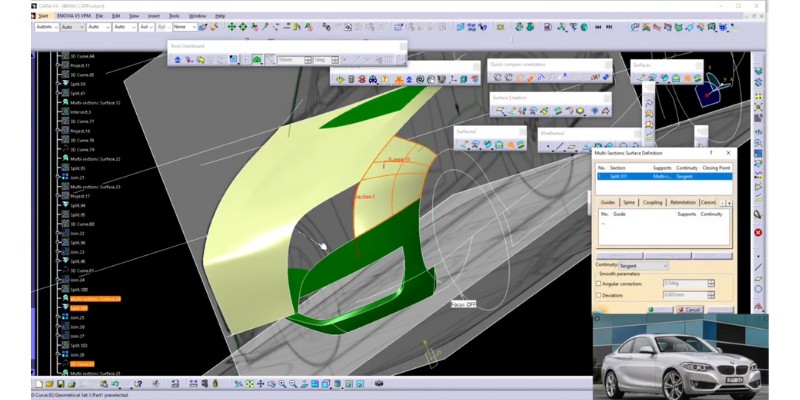

CATIA Has Superior Surface Modeling

Surface modeling is a major step in designing aircraft, cars, spacecraft, ships, and oil and gas infrastructure. For example, designing an airplane requires simulating its aerodynamic behavior.

CATIA is better than SolidWorks in surface design and simulation. Boeing, Tesla motors, and BMW are some industries that use CATIA.

CATIA Has Superior Large-Scale Collaboration

CATIA can manage hundreds of designers who work simultaneously on various parts of a design. SolidWorks also allows collaboration between teammates, but CATIA’s project management is more powerful and large-scale than SolidWorks’. CATIA can also integrate the assemblies and simulate large-scale projects

CATIA Has Superior Large-Scale Simulations

SolidWorks’ ease of use is a disadvantage in extensively large designs that merge thousands of parts. SolidWorks doesn’t run these huge projects as smoothly as CATIA, and may even crash. Because SolidWorks is user-friendly, while CATIA is machine-friendly.

A few years ago, my friends who were mechanical engineering students used to reserve computers to run SolidWorks simulations since it took so long. And sometimes it would crash after so much waiting!

Imagine simulating a larger project that should integrate assemblies from tens of designers. That’s why CATIA is the industry standard in large-scale designs.

Which is better, CATIA or SolidWorks?

Although CATIA and SolidWorks are from the same company, they aim at different industries. SolidWorks is better than CATIA for part-making and medium-sized projects since SolidWorks is far easier than CATIA to use and learn. However, CATIA is better than SolidWorks for surface design and very large projects.

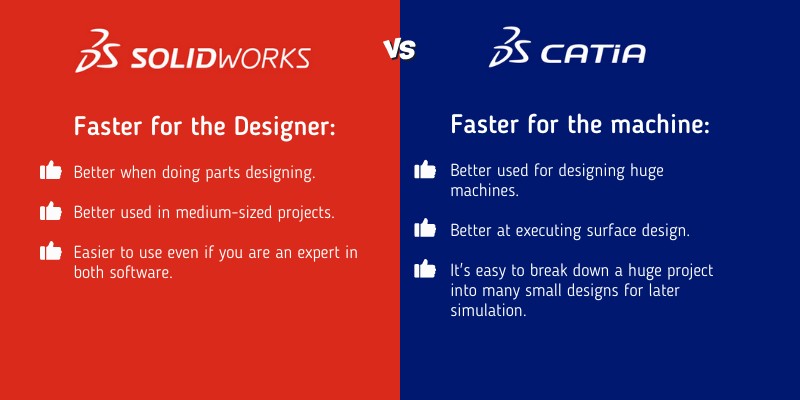

Which is faster, CATIA or SolidWorks?

SolidWorks is faster for the designer, while CATIA is faster for the machine. Therefore, SolidWorks is faster for designing parts, while CATIA is faster for designing large machines.

I’ve seen parts that take 30 minutes with SolidWorks to design, while they will take 55 minutes with CATIA. Therefore, SolidWorks is better than CATIA for medium-sized projects, because SolidWorks is simpler and has more straightforward design logic. But these are simple models.

On the other hand, CATIA can break down a large project into many design fragments. Then, it will manage and simulate much faster than SolidWorks. So CATIA is faster than SolidWorks on the machine side.

Applications

We’ve seen that CATIA is best for large machinery, while SolidWorks is best for medium-sized designs.

Therefore, a car company may use CATIA to design a car, while the parts manufacturers may use SolidWorks.

That’s why SolidWorks sells over three times more than CATIA. As of now, 46426 companies use SolidWorks, while 15351 companies use CATIA.

Aerospace companies, oil and gas industries, ship manufacturers, and automotive industries use CATIA. Although these are big companies, they are smaller in quantity.

On the other hand, most manufacturers from toys, to parts, tools, engineering products, and appliances use SolidWorks.

To verify this trend, here are just some of the names that use CATIA and SolidWorks:

Some brands that use CATIA:

- Boeing

- Tesla Motors

- Solar Impulse

- Ashok Leyland

- Land Rover

- BMW

These companies use CATIA because it handles big projects and is excellent for surface design.

Meanwhile, the following names use SolidWorks:

- Bosch

- Omax

- Norbord

- Haumiller Engineering

These companies choose SolidWorks over CATIA for its ease of use in building parts since their projects are medium-sized.

Price

Although Dassault Systemes doesn’t release an exact price (since you’ll need consultation on what you need), one CATIA license costs between $9000 and $65000. CATIA’s price depends on the features and capabilities you order.

CATIA is one of the most expensive software out there. But, its price matches the industries that use it. As we’ve already mentioned, CATIA is suitable for large-scale industries like aircraft design.

You can buy SolidWorks from a reseller. Consider the following when buying SolidWorks.

- SolidWorks is almost free for students, artists, and new startups. For example, artists can use SolidWorks for only $99 per year.

- Choose your plan. SolidWorks Standard costs about $4000 (or $2700 per year), and SolidWorks Professional is in the $5500 ballpark. Finally, SolidWorks Premium is in the $8000 region (or $4825 yearly).

- You can also pay about 15-20% of these prices annually as a maintenance fee. This will get you package upgrades and technical support.

SolidWorks is cheaper than CATIA, but not by as much as it seems. Because you may need to buy add-ons depending on your needs. Some SolidWorks add-ons are pretty expensive.

For example, the Simulation add-on costs $4195 (different SolidWorks packages have various simulation capabilities, but the Simulation add-on brings in all the simulating power). Or, the SolidWorks Geomagic add-on costs $7900.

Summary

SolidWorks and CATIA are two excellent CAD software from Dassault Systemes. They can create 2D drafts, 3D models, assemblies, parametric designs, input-output simulation, fluid dynamic simulation, material stress simulation, reverse engineering, and more.

SolidWorks is easier to use than CATIA. Therefore, SolidWorks is more efficient in designing parts or average-scale machinery. SolidWorks has plenty of add-ons to bring in any capability you demand.

CATIA manages, models, and simulates large machinery better than SolidWorks. However, it’s harder to learn.

While industries that build average-size machinery demand SolidWorks skills, learning CATIA sends you to companies with large machines like cars and aircraft.

Related posts:

- [Compared] FreeCAD vs Fusion 360: Which Is The Best CAD For You?

- AutoCAD vs SolidWorks: Comparison

- Onshape or SolidWorks: Which is Best?

- The Best Free CNC (CAD, CAM, Control, and Firmware) Software

- Ranking The Best 3018 CNC Software for Amateurs

- Top Free & Paid Laser Engraving & Cutter Software

- Noteworthy CAD CAM Software For All Uses