Key Takeaways

- Laser etching metal: Laser etching is a process of marking a metal by slightly melting its surface with a laser. It is fast, cheap, and creates high contrast.

- Fiber vs CO2 lasers: Fiber lasers can etch metals directly, while CO2 lasers need special sprays to etch metals indirectly. Fiber lasers are better and faster for etching metals.

- Metal compatibility: You can etch various metals, such as steel, aluminum, copper, gold, silver, titanium, and brass. Steel and aluminum are the easiest metals to etch with lasers.

- Etching techniques: There are two etching techniques depending on the laser type. Fiber lasers can etch metals directly by adjusting the laser settings. CO2 lasers can etch metals indirectly by applying and cleaning sprays.

Laser etching metal is pretty handy for brands and part manufacturers. If you look around you, you’ll see bar codes, UDIs, logos, and pictures that were etched by lasers.

For these particular markings, etching is better than engraving – which we’ll explain in this article. Metal laser etching is faster, cheaper, and has higher contrast than laser engraving metal. Also, etching retains part integrity better than engraving.

Material-wise, you can laser metal etch steel, aluminum, anodized aluminum, gold, silver, copper, brass, titanium, and more.

Fiber lasers and CO2 lasers can both etch metals, though with different etching techniques. Fiber lasers are better for laser etching metals since they can etch metals directly, and at higher speeds.

On the other hand, CO2 lasers need an etching spray to etch metals. This laser etching technique also works with fiber lasers, although it’s seldom necessary. We’ll explain both laser etching techniques later in this article, and we have also previously written about the best lasers for etching and engraving metal.

- Key Takeaways

- What is Laser Etching on Metal?

- What Is the Difference Between Laser Etching, Laser Engraving, and Laser Marking Metal?

- Can a Laser Engraver Etch Metal?

- What Type of Laser Can Etch Metals?

- What Metals Can Be Laser Etched?

- How to Etch Metals With a Laser Engraver

- Color Laser Etching Metals

- Summary

- FAQs on laser etching metal

What is Laser Etching on Metal?

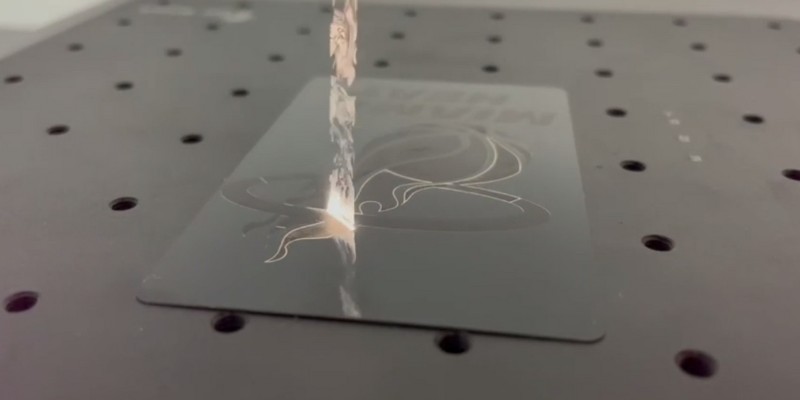

Laser etching is the process of marking a metal by slightly melting a very small amount of the metal’s surface (around 0.08mm) with a laser. Laser etching is the most common marking method for products and parts, since it’s fast and effective. Other laser-marking methods include engraving, annealing (marking), and laser ablation.

What Is the Difference Between Laser Etching, Laser Engraving, and Laser Marking Metal?

Laser engraving metal creates much deeper cavities in the metal (around 0.5mm) than etching (around 0.08mm).

In engraving, the laser carves the metal by vaporizing the metal’s surface, whereas in etching the laser melts the metal so that it can solidify back on the surface, and laser marking involves heating the metal enough that its surface undergoes a chemical reaction. Laser marking a metal retains its surface properties and is very durable.

Advantages of Laser Etching Metal

- Laser etching is faster than engraving since the laser requires less time and power to melt the surface (instead of evaporating it).

- Laser etching is cheaper than engraving, since it is faster and requires less energy.

- In general, laser etching creates better contrast than laser engraving. While etching creates black or white marks against the background, engraving may or may not change the metal’s shade.

- However, laser etching is not as durable as engraving since the marks are above the surface and wear off with abrasive treatment. Still, laser etching survives the part’s entire life under normal conditions.

Can a Laser Engraver Etch Metal?

Yes, laser engravers can also etch metals. Any laser that can engrave metal can also etch it, since laser etching metals requires less energy than engraving.

Lasers that can’t even engrave metal may still be able to etch metal, depending on the technique, the laser, and the metal. We’ll explain this next.

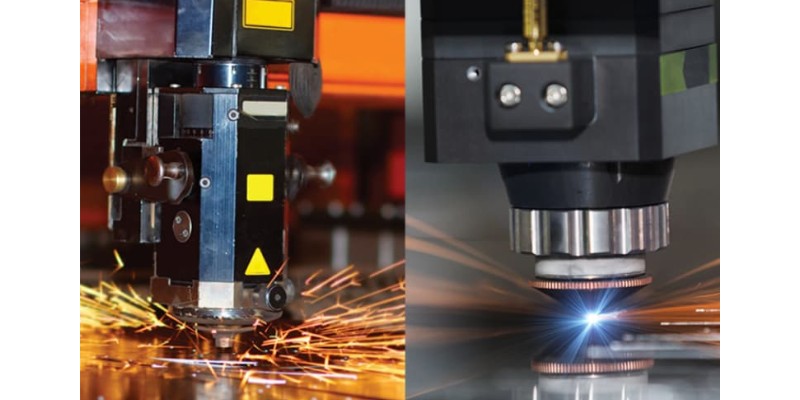

What Type of Laser Can Etch Metals?

Fiber and CO2 lasers can both laser etch metals.

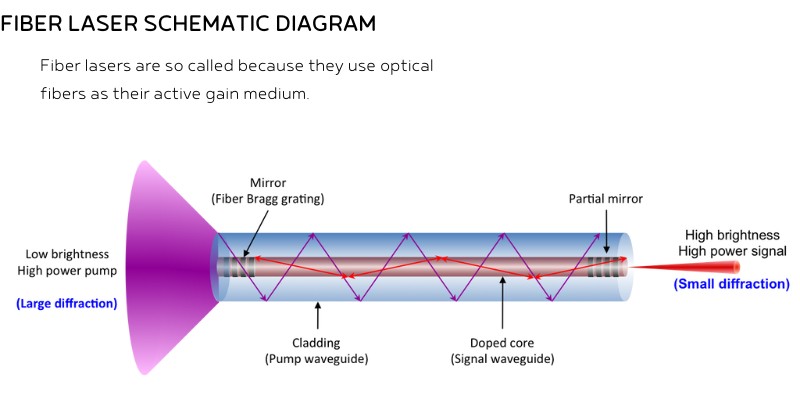

Fiber lasers can etch metals directly, while CO2 lasers can etch metals indirectly using special sprays. This makes fiber lasers better and faster than CO2 lasers for etching metals.

Diode lasers may also etch with some spray brands, at very slow speeds. However, don’t expect their etching to last as long as CO2 or fiber lasers.

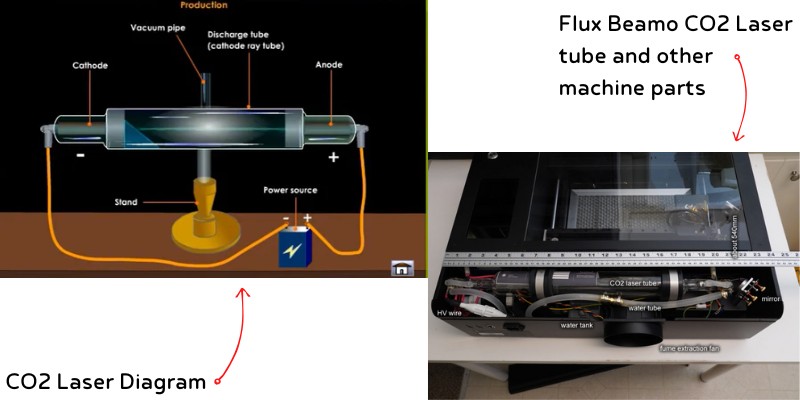

A fiber laser’s beam has a different wavelength than a CO2 laser. Metals absorb the fiber laser’s beam, while they reflect a CO2 laser’s beam. Hence, only fiber lasers can etch metals directly.

However, there is an artificial method for etching metals using CO2 lasers. This involves preparing the metal’s surface with special sprays, and etching the spray on the metal’s surface.

Advantages of Fiber Lasers Over CO2 Lasers in Metal Etching

Fiber lasers are better than CO2 lasers at etching metals for the following reasons:

- CO2 lasers require the metal’s surface to be treated prior to etching. Also, you’ll need to wash the chemicals off after finishing. This takes more time and effort overall.

- A CO2 laser needs more power (wattage) to etch metals since metal doesn’t absorb the CO2 laser’s beam well. Even a 40W fiber laser etches steel far better than a 100W CO2 laser.

- Fiber lasers can etch metals much faster than CO2 lasers. CO2 lasers need slow speeds to bond the spray to the metal’s surface effectively. Using high speeds to etch metals with a CO2 laser results in etchings that easily wipe off.

- Fiber lasers create more durable metal etchings than CO2 lasers on some materials like aluminum. This is because fiber lasers bond the metal oxide to the metal, while CO2 lasers bond the spray to the metal surface.

What Metals Can Be Laser Etched?

You can etch various metals including steel, aluminum, anodized aluminum, copper, gold, silver, titanium, brass, and galvanized metals.

Steel

Laser etching steel is one of the easiest of all metals, steel absorbs laser beams remarkably well. This makes laser etching steel fast, and doable with more lasers (since it doesn’t require as much laser power as gold, for example).

Lasers can etch mild steel, high-speed steel, and stainless steel. However, laser marking stainless steel is better than etching since marking retains stainless steel’s anti-corrosive and anti-abrasive properties better than etching.

Iron

Iron is easy to etch, but pure iron will rust in no time and the etching will wear off. So, iron is not a good metal for laser etching.

Aluminum

Laser etching aluminum is easy, practical, and long-lasting.

Silver, Gold, and Copper

Etching silver, gold, and copper with fiber lasers is more demanding than etching steel and aluminum. You’ll need more power to etch silver, gold, and copper. However, green lasers (or double-frequency fiber lasers) can etch these metals quite easily.

How to Etch Metals With a Laser Engraver

Laser Etching Techniques

There are two metal laser etching techniques depending on the laser type. Fiber lasers can directly etch metals since metals absorb the laser beam.

On the other hand, A CO2 laser can only etch with sprays or pastes. If you use a diode laser, you should also use this method.

So, choose your laser etching technique based on whether you have a fiber laser or a CO2 laser.

However, preparing the design file is similar in both laser etching techniques.

Step 0: Create the Design File

You can use a photo, or your own design for laser etching. However, you must turn the image to grayscale.

Since laser etching results in monochromatic marks, you can only laser etch black and white images. Then, save the file in a format your laser recognizes.

Lightburn is a popular laser design and control software. But you can also use Photoshop, EzCad 2, CorelDRAW, and countless other graphic or CAD software you like.

How to Laser Etch Metals With a Fiber Laser

Fiber lasers can etch all metals directly. All you need to do is open the file from step 0 in your laser’s control software and start etching.

Also, cleaning the metal’s surface before etching enhances the results. We’ll explain this more in the etching spray technique.

Here are some things to consider when laser etching metals with a fiber laser.

- Fiber lasers don’t require paint, dye, or any chemical sprays to etch metals.

- Your laser manufacturer should provide the correct laser settings for etching different metals. So, look up the metal you want to etch in your manufacturer’s manual.

- Etching around cylindrical metals requires a rotary. However, you can still etch on parts of curved metals without a rotary. You can stretch the text in your design to compensate for the warping effect. You should also adjust the laser’s focus at the average height of the curved surface.

Do Metal Etching Sprays Work With Fiber Lasers Too?

Yes. Although fiber lasers can etch metals directly, you can also use the spray method with fiber lasers if you want the spray’s particular color. However, it’s not customary to spray the metals for fiber lasers since the spray etching technique is more laborious.

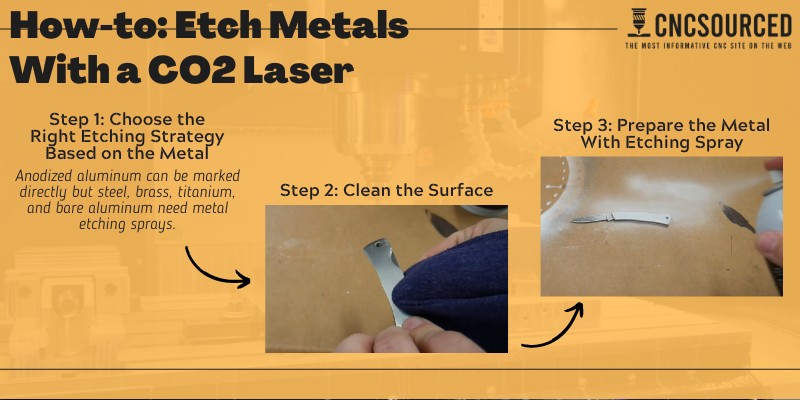

How to Etch Metals With a CO2 Laser

1. Choose the Right Etching Strategy Based on the Metal

You can mark anodized aluminum and any painted metal directly. In this case, you’ll need laser ablation – not laser etching. Using a CO2 laser on anodized aluminum is technically laser ablation – but many call it engraving anyway. You’ll only need to follow steps 2 and 4 below in this case.

However, to etch any other metal like steel, brass, titanium, and bare aluminum, you must follow all of the steps below.

2. Clean the Surface

Your metal surface could have dust, grease, or rust on the surface, so it’s important to clean the surface to get the best results.

Grease and dust particles reduce the effective laser beam power, and also, rust or metal oxides have different melting points than bare metal. This will interfere with the etching, and affect your results.

- Use alcohol (methanol, ethanol), or other industrial cleaners to clean the surface from dust and grease.

- Use fine-grit sandpaper to remove rust and corrosion from the metal’s surface.

3. Prepare the Metal With Etching Spray

You need to coat the metal with the right chemicals. There are spray inks and pastes for laser etching metals. Some people have also tried other materials like mustard for laser etching steel. It works, but the quality is poor. We’ll recommend some high-quality sprays here.

Laser Etching Sprays for Metals

Brilliance Laser Inks is a high-quality aerosol that will etch black ink to your metal. Check out its price on Amazon. The result is long-lasting black marks on your metal.

Laser Bond 100 is also a popular laser etching spray. It’s more expensive than Brilliance Laser Inks, however, LB100 can also etch on glass and ceramics (while BLI aerosol can’t). Check out its price on Amazon.

I recommend you put the metal on a piece of scrap wood, since the spray will get around the metal and cause a mess otherwise. You can also use masking tape to avoid spraying beyond where you intend to.

Also, it’s best to apply these sprays in the open air, or a room with proper ventilation.

4. Etch the Metal

After the spray dries, you can etch the chemical to the metal with your laser. Send the file you saved in step 0 to your laser’s control software and start etching. Exercise safety measures, especially since metals reflect most of the CO2 laser beam.

You should use high laser power and slow speeds with CO2 lasers. It’s best to test different laser speeds on scrap material and compare results, since CO2 lasers and different spray brands are not as consistent as etching metals with a fiber laser.

5. Clean the Metal

After laser etching, you’ll need to clean the spray off the metal. You can wash off some sprays like Brilliance Laser Inks easily with water, while you need alcohol to clean some other sprays.

Recommended Steel Laser Etching Machines

Fiber lasers with 50W of laser power (or more) are excellent for etching metals. Having a rotary is also a plus for etching rings and curved metals. So, I’ve recommended one product below for its great value and affordability.

The Cloudray Raycus 50W Fiber Laser has a high value-to-price ratio. At this price on Amazon, you’ll get a powerful fiber laser with a rotary axis. It includes EzCad2 Lite and is compatible with Lightburn.

Plus, you can order this steel laser etching machine in various sizes, from 4.3” by 4.3” (110x110mm) to 11.8” by 11.8” (300x300mm).

Color Laser Etching Metals

Colorful laser marks on metals are impressive. Some companies prefer colored etchings to imrpvoe their brand visibility on pens or flashlights, but it can also be an artistic pursuit.

There are two methods for creating metal engravings in color: no-contact, and hands-on methods.

MOPA fiber lasers can directly color-mark metals without human contact. Alternatively, you can color the engravings yourself by color-filling techniques, or baking dye powder with your laser. We’ve explained all the techniques in this article.

Summary

Metal laser etching is one of the most popular marking techniques for creating logos, 2D matrix codes, bar codes, product information, and more.

Fiber lasers and CO2 lasers can etch metals, however, fiber lasers are the natural choice for laser etching metals. Laser metal etching by fiber lasers doesn’t require chemical agents and has fantastic speed.

However, laser etching metals with a CO2 laser involves etching sprays and a different etching technique.

FAQs on laser etching metal

What is the best metal for laser etching?

The best metals for laser etching with an ordinary laser are mild steel, stainless steel, and aluminum. These metals (in that order) can highly absorb a fiber laser’s beam. Steel is the best metal for laser etching and is the only metal that can even absorb about 10% of a CO2 laser’s beam.

Is laser etching permanent? / Does laser etching wear off / Does laser etching last?

Laser etching lasts the part’s useful life under normal conditions. However, laser etching doesn’t survive any abrasive treatment. Since etching stands above the surface under a microscope, any abrasion can wear it off.

What laser do I need to etch metal?

You need a fiber laser to etch metals. Laser etching metals with a CO2 laser requires an artificial method that takes labor and contact from the user. Finally, special double-frequency fiber lasers are overwhelmingly more effective than normal fiber lasers for etching gold, silver, and copper.

How fast is metal laser etching?

Laser etching metal is much faster than engraving or marking it. Since engraving requires more energy than etching, engraving metals is not even half as fast as etching metals. Also, higher-power lasers can etch metals faster.

Can Diode Lasers Etch Metals?

To some extent, yes, but you should manage your expectations. Although metals absorb their beam well, diode lasers are too weak to directly etch metals. On the other hand, if you use slow speeds between 6-20mm/sec and 100% power, you can etch some spray brands (like LBT 100) to the metal. However, the diode laser etching may wear off faster than high-quality etchings.

Related articles:

- A Comprehensive Guide to Laser Engraving & Etching Anodized Aluminum

- What is Laser Air Assist? Here’s A Complete Guide

- Color Laser Engraving Techniques [Explained]

- What Is: Laser Engraving vs Etching vs Marking? [Guide]

- Top Ranked Jewelry Engraving Machines Today!

- Best Metal Laser Etching & Engraving Machines

- Which Materials Can Lasers Cut and Engrave: The Complete Guide