Key Takeaways

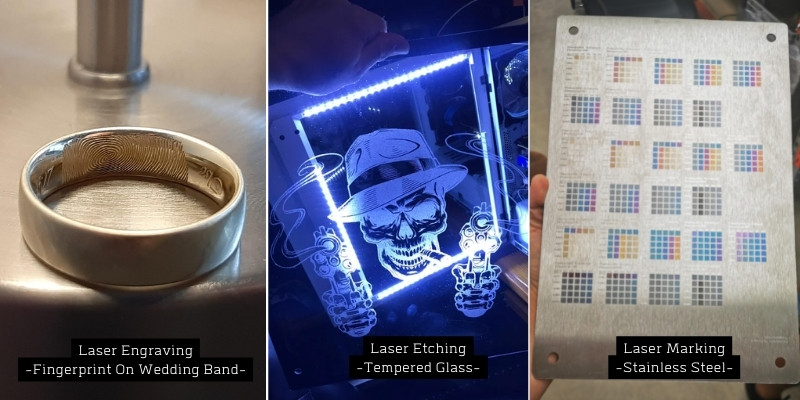

- Laser marking techniques: There are three main techniques of laser marking: engraving, etching, and marking. They differ in how they interact with the material and the resulting surface properties.

- Laser engraving: Laser engraving vaporizes the material and leaves a cavity. It can create custom designs, but it is slower, more expensive, and less contrasted than etching.

- Laser etching: Laser etching melts the material and creates a slightly raised surface. It is fast, cheap, and high-contrast. It is suitable for most materials, except stainless steel.

- Laser marking: Laser marking stains the material through a chemical reaction. It does not disturb the surface physically. It is ideal for stainless steel and can create colors on metals.

Objects all around us bear markings, such as logos or ID codes, making laser marking ideal for both identification and marketing purposes. Some industries even have regulations that mandate marking tracking information.

Metal laser machines are the best method of marking metal. Lasers mark materials using laser engraving, etching, and laser marking.

So, what is the difference between engraving and etching? Not to worry, we’ll show you examples of laser engraved and laser etched materials and explain all the distinctions.

This article explains the difference between engraving and etching (and marking), their resulting surface properties, the color contrast, and the materials suitable for each technique. We will also compare their speed and cost and explain which practice best suits the different laser marking needs.

- Key Takeaways

- The Differences Between Laser Engraving, Etching, and Marking

- What Is Laser Engraving?

- What Is Laser Etching?

- What Is Laser Marking?

- How Can You Tell The Difference Between Etching and Engraving?

- Are Laser Etching Machines and Laser Engravers the Same?

- Comparing Traits: Engraving vs Etching vs Marking

- Does Laser Etching Wear Off?

- Why Is Engraving More Expensive Than Etching?

- What Are the Advantages of Etching Over Engraving?

- What Are the Advantages of Engraving Over Etching?

- Final Thoughts

The Differences Between Laser Engraving, Etching, and Marking

Laser engraving scrapes off the material and leaves a cavity, while laser etching delivers a slightly raised surface. Also, laser marking stains the material chemically, so the surface remains intact physically.

Laser engraving vaporizes the material, while laser etching melts the material and allows it to solidify back.

In short, etching is the fastest and most-effective technique with high contrast. Instead, engraving survives abrasion and offers more customization. Meanwhile, laser marking is perfect for stainless steel, and offers coloring.

What Is Laser Engraving?

In laser engraving, the laser concentrates a high quantity of energy to remove the material. The material vaporizes away from the surface and leaves a cavity. You can see the void space or feel it by touch.

Although laser engraving is not as fast as laser etching, it is still pretty fast. Engraving lasers utilize wavelengths and pulses that transmit intense amounts of energy. Therefore, they can vaporize the material fast.

You can adjust the depth of laser engraving. The laser can engrave deeper by going over the same area with more passes.

Therefore, laser engraving allows customizing the material’s surface. This trait is unique to engraving: you can vary the number of passes and the output power to penetrate different depths and achieve custom surface designs.

Materials That Can Be Laser Engraved

You can laser engrave almost anything. Lasers can engrave plastics, wood, metals, glass, and more. However, it is unwise to laser engrave a few materials like stainless steel.

See also: our ranking of the best glass laser engravers for a small business

Some materials have a top layer or coating that you should not disturb. For example, stainless steel has chromium on its surface, which makes it resistant to corrosion and scratching. Engraving stainless steel means removing its anti-corrosion layer and exposing it to harm.

Similarly, engraving a painted or coated material bites the protective layer. Laser engraving is the most intrusive laser marking technique. So, engraving is not appropriate for materials that will suffer safety issues from scratching their surface.

Contrast In Laser Engraved Materials

Laser engraving creates contrast only when it chars the material. So, the results from laser engraving can range from no contrast to moderate burning contrast.

However, laser engraving can create high contrast in the laser ablation process.

What Is Laser Ablation?

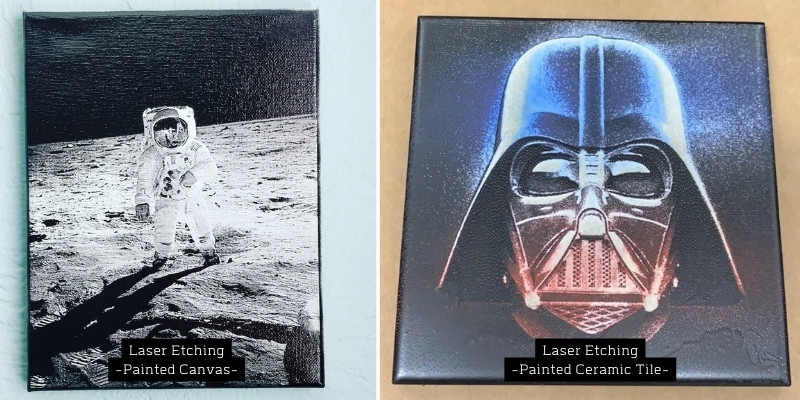

Laser ablation is when you engrave a coated material to remove its coating. Laser ablation is a type of laser engraving.

Usually, the material has a coating of paint or an anodized layer. Typically, the coating and the raw material beneath it have different colors.

So, when the laser ablation removes the top layer by engraving, it reveals a different color underneath.

However, generally, laser engraving creates a lower contrast than laser etching.

Applications of Laser Engraving

Laser engraving is great for creative projects. Engraving is also an efficient tool for creating bar codes, part numbers, and other tracking information.

What Is Laser Etching?

In etching, the laser transmits enough energy to melt the material. Then, the melted spot darkens, expands a little, and solidifies back (rapidly). So, etching leaves a slightly raised surface with a high-contrasting color.

Laser etching is the fastest laser marking technique. Etching is also the most cost-effective method.

Therefore, etching is the most widely used technique for printing data matrix codes, bar codes, logos, and other information on most materials.

Laser etching also requires penetrating the material’s surface (like engraving). However, laser etching does not penetrate as deeply as engraving does.

Laser etching penetrates the material 0.001” (in metals), while engraving penetrates up to 0.02” in metals. So while small, engraving penetrates the material about 20 times deeper than etching.

Laser etching also results in a different surface than laser engraving. Since the melted material solidifies back in laser etching, it creates a texture slightly above the surface.

Can You Laser Etch Stainless Steel?

You can laser etch most metals, not to mention wood, plastic, and most other materials. However, laser etching stainless steel is wrong for the same reasons engraving it is wrong: you should not physically disturb stainless steel’s surface.

Although laser etching does not scratch as deep as engraving does, etching still intrudes on the material physically.

Therefore, laser marking suits stainless steel best. When we explain laser marking, we’ll see that etching and engraving are intrusive methods, while laser marking keeps the material’s surface intact.

Can You Laser Etch Glass?

Glass etching machines are also trendy for glass etching bottles. However, there are two types of glass etching.

In one technique, the glass etching machine uses acids for marking. Alternatively, lasers can create glass etching as well. Even ordinary CO2 lasers can fashion fine glass etchings.

What Is Laser Marking?

Technically, all manners of leaving a trace on material with a laser are marking, including engraving and etching.

But, laser marking refers to staining the material through a chemical reaction. In laser marking, the laser slowly heats the material. The heated spot oxidizes and therefore blackens.

This staining method is less common since laser marking costs more than laser etching. However, it has many applications in medical, automotive, airspace, and other industries.

As we have explained, laser marking is the best marking technique for stainless steel. And the above industries exhibit numerous stainless steel parts that need UIDs (unique identifiers).

Laser marking has different methods and tremendous other abilities: annealing, coloration, foaming, and carbon migration are different types of laser marking.

Laser marking has impressive capability in creating colors on metals. You can color print on metals with laser marking.

Laser marking can also create a range of colors on plastic. But, the color range always retains the original plastic color’s shade. So, coloring plastics by laser marking is not as versatile as coloring metals.

How Can You Tell The Difference Between Etching and Engraving?

Let’s summarize the etching vs engraving differences that we can immediately detect on any material by sight and touch.

- A laser engraved surface contains cavities, while laser-etched surfaces are slightly raised.

- Laser etching generally creates a higher contrast than laser engraved marks.

This picture shows my table tennis blade. There is black text on its face and a serial number on its bottom right-hand side. I’ve outlined them. The text is laser etched, while the serial number is laser engraved.

Now, we compare laser engraving vs etching on the blade.

Texture: Etching vs Engraving

The laser engraving is about 1mm deep (0.04”). I can insert my nail a little inside the serial number. However, this engraving wouldn’t have been deeper than 0.5mm if we had metal instead of wood here.

On the other hand, the wood etching has not created any cavities. The wood etching has raised the micro-surface a little, but not enough for me to feel the wood etching by touch. However, in some etchings, you can actually feel the raised text with your nails.

Contrast: Engraving vs Etching

Laser etching has created a black text with high contrast against the blade’s face. But laser engraving has not made any contrast.

Using this example, you can see whether the instruments around you have etchings or engravings.

Are Laser Etching Machines and Laser Engravers the Same?

Laser machines come in various types and have diverse abilities. So, are laser etching machines different from laser engravers?

Generally, fiber lasers are better for etching, while CO2 lasers are better for engraving. However, this depends on the material too.

These two lasers have different wavelengths. So, their beams interact with materials differently. For example, CO2 lasers can’t engrave or etch metals directly since their beam reflects from metals’ surfaces. While CO2 lasers need special sprays to engrave metals, fiber lasers work on metals directly.

However, there are no rigid lines separating laser etching machines from laser engravers. Depending on the material, both lasers may be able to engrave or etch with the right settings.

Comparing Traits: Engraving vs Etching vs Marking

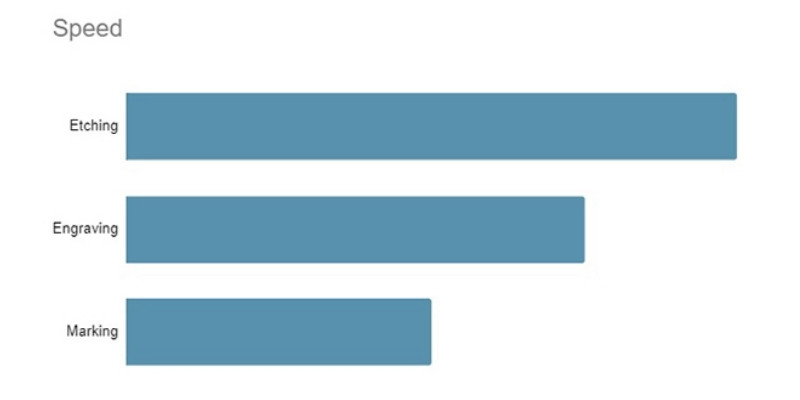

Speed: Engraving vs Etching vs Marking

Although laser engraving is pretty fast, etching is the fastest marking method. Meanwhile, laser marking (by chemical reactions) is the slowest marking technique.

Laser annealing and other marking techniques are slow since the laser has to heat each spot slowly until it reacts with oxygen.

Laser etching is faster than engraving since it requires less beam power.

Material Depth Penetration: Engraving vs Etching vs Marking

Engraving penetrates a material deeper than laser etching. Laser engraving can go as deep as 0.02” (0.5mm) in metals (and much deeper in wood). However, laser etching interacts with the upper 0.001” (0.03mm).

| ↓Technique→Effects | Beam’s Physical Penetration (Metals) | Can Repeat Passes Go Deeper? |

|---|---|---|

| Engraving | Up to 0.02” (0.5mm) | Yes |

| Etching | 0.001” (0.03mm) | No |

| Marking | 0 (Theoretical) | NA |

While engraving leaves a deep cavity, etching barely scratches the surface.

Moreover, laser marking does not invade the material at all. In annealing, for example, the laser only heats the metal until it blackens without disturbing the surface physically.

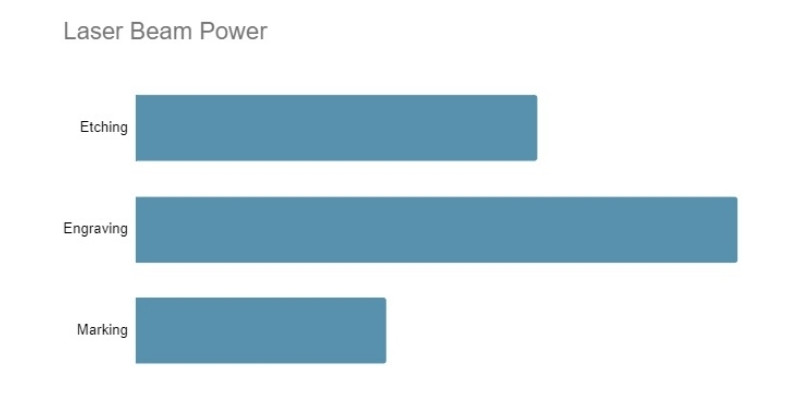

Laser Beam Power: Laser Engraving vs Etching vs Marking

Laser engraving vaporizes the material, while etching melts the micro-surface. What’s more, engraving penetrates deeper than etching.

Therefore, laser engraving requires much more beam power than laser etching.

Also, laser marking demands less beam power due to its slow character.

Contrast and Color: Etching vs Engraving vs Marking

Laser etching can create white or black marks against the background color. Moreover, the resulting raised surface in laser etching is not smooth under a microscope. The unsmooth surface changes the light reflection properties of the etched areas. Therefore, laser etching generates high contrast.

On the other hand, as we’ve seen with the table tennis blade, laser engraving can’t generally create much contrast. However, one specific type of laser engraving delivers high-contrast engravings: laser ablation.

We’ve also seen laser marking’s tremendous abilities in creating different colors and contrasts.

Does Laser Etching Wear Off?

Yes. Laser etching creates a slightly raised surface, and so disappears after abrasive treatment or harsh scratching. However, laser etching lasts long under normal conditions.

Laser engraving is more durable than laser etching. An etched marking’s life depends on whether the material is subject to abrasion.

Engraving marks deeply inside the material, while etching creates a thin raised surface. Therefore, engraving can survive massive scratches, while etching perishes with any abrasive treatment.

So, a laser etched text wears off if you keep rubbing it with a rough object.

This principle applies to the production process too. If there is abrasive treatment in production (such as sandblasting), it always precedes laser etching. However, laser engraving can stand abrasive treatments as well. So, you can sandblast an engraved surface as well.

Why Is Engraving More Expensive Than Etching?

Laser etching is the most cost-effective laser marking technique. Engraving is more expensive than etching for two reasons.

Firstly, laser engraving demands a more powerful laser beam. The laser beam for engraving penetrates deeper than etching and has to transmit more energy to vaporize the material.

Secondly, laser etching is faster than engraving. So, etching claims less production time.

Sometimes, laser engraving services charge less for engraving a few materials. But, etching is always cheaper than engraving in high quantities.

What Are the Advantages of Etching Over Engraving?

Laser etching is better than engraving in most cases for creating bar codes, logos, or any identification needs. Because laser etching has several advantages over laser engraving.

Laser etching is faster than engraving. And rapid processing is crucial to all industries.

Moreover, etching generally yields better contrast than engraving. So, unless the aim is laser ablation, etching gives higher contrast than engraving.

Finally, etching is cheaper than engraving.

What Are the Advantages of Engraving Over Etching?

There are several benefits to laser engraving that etching lacks.

Custom physical designs on the material’s surface are possible with laser engraving: you can penetrate various depths by changing the number of passes and output power to create custom surface designs.

Also, laser engraving is more durable than etching. A laser engraved material retains its marks even after it suffers severe abrasion.

For example, sandblasting an instrument’s surface (for removing corrosions and dirt) is possible if the part bears laser engravings.

Final Thoughts

Engraving, etching, and laser marking are different techniques of laser marking. Sometimes we use these terms interchangeably, but the methods are dissimilar.

Laser engraving penetrates deeply into the material and leaves a cavity behind. Engraving can have low contrast. Laser engraving works on most stuff.

Laser etching penetrates little into the material and causes a raised surface. Laser etching can mark in white or black to create a high contrast against the background color.

Laser marking causes the material to react chemically and change colors. It is the best marking method for stainless steel.

Laser etching is the fastest marking method and is the best choice for most tracking and logo marking needs.

Laser etching is more cost-effective than engraving. Meanwhile, laser marking is the most expensive marking method.

If you’re looking to purchase a laser, here are our recommendations:

- The Best Affordable Laser Engravers for Metal

- The Best Laser Cutters and Engravers – Overall Recommendations

For picking between brands, or project ideas:

- Easy Glowforge Projects You Can DIY And Sell

- Best Free & Paid Laser Engraving & Cutter Software

- Which materials can you laser cut and engrave?

- Laser etching metal – a how-to guide (and the best lasers for laser etching)