Making a CNC guitar is an incredibly satisfying project – but it can be tricky to get right, even for the most basic designs.

The shape needs to be just right to get the sound you want, and just an inch or two of difference between separate pieces will have it basically useless at best, and falling apart at worst.

With that said, it is possible to make your own guitar from CNC files for a greater connection with your instrument (or to simply make money with your CNC router).

First up, you’ll need the right files – and while many sites offer them, most aren’t reliable.

In my opinion, Etsy is the best and most reliable site for trustworthy CNC guitar designs, with plenty of customer reviews you can asses before committing to a cut.

They may cost a few dollars, but it’s worth it to get a good end result. Otherwise, Thingiverse offers a lot of free CNC guitar files you can consider, too

In this guide, I’ll show you some of the best and most CNC guitar designs I’ve found online, as well as some important pointers to help make your project a success.

Take it from me – this is not the sort of project you want to rush!

Where to Find CNC Guitar Files

There are a lot of sites where you’ll find CNC guitar files, but with something as time-consuming and complex as making a guitar from scratch, you’ll want to make sure you’re getting something tried and tested.

Keep in mind that not every file from even the most trustworthy of sites is going to be perfect. Reading consumer reviews and doing your own analysis before dedicating yourself to a purchase or project is always a good call.

Failed projects or subpar designs are a waste of time, materials, and money, so it’s important to make sure you know exactly what you’re getting before you get too excited.

Thingiverse

A lot of the CNC guitar files found online cost money, but Thingiverse comes to the rescue by offering a platform for guitar designers who just want to share their creations with the world.

While free CNC guitar files are difficult to come by, especially if you want something reliable and user-reviewed. Be sure to look around before deciding to open your wallet!

You can find just about anything like this traditional guitar body. Our favorites, however, are the more creative designs like this design that’s basically like a standalone sitar.

Etsy

The sad truth about CNC guitar files is that you’re going to have to roll up your sleeves if you want to find designs you can trust. Many online CNC guitar files are marred with terrible reviews regarding incorrect sizes, design mistakes, and inconsistencies that have left many a prospective guitar builder in a rut.

Personally, I found Etsy to be the best and most reliable site for trustworthy CNC guitar designs by far.

Etsy isn’t just for baskets and blankets, plenty of CAD software wizards have uploaded their projects to the much-loved site for independent creators of all kinds.

There are plenty of guitar CNC files available here. Some of our favorites include this Gibson-style Firebird for a cool spin on an old electric guitar, as well as these Retrovibe plans for a more classic look.

If you want to make something a little simpler (and a little less flashy) then you, like me, will get a nice nostalgic kick out of these CNC guitar files for an old-school Dreadnaught acoustic. As a former acoustic player myself, I’ve had this one bookmarked for a while.

Each of these designs comes from John Anthony Guitars, who has had remarkable positive reviews across all his creations.

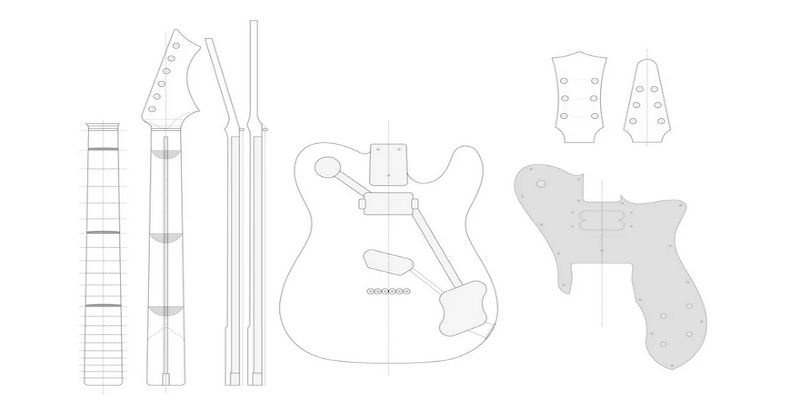

However, if you’re only looking for specific body parts to add to or customize a pre-existing design of your own, then you’ll be happy to learn that you’ll also find parts like this body outline or these CNC guitar neck files.

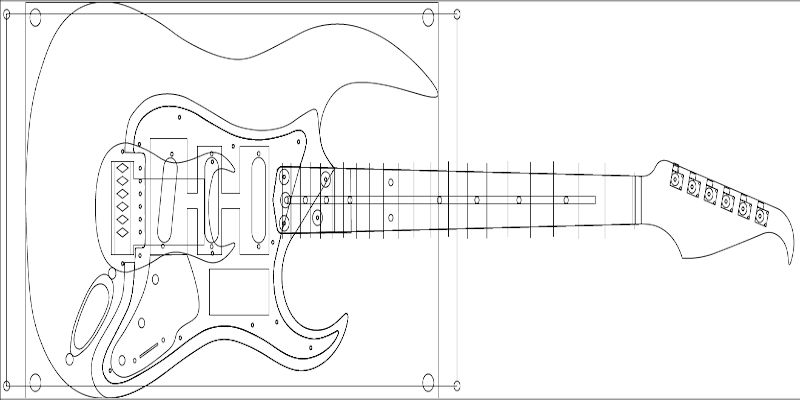

2D CNC Electric Guitar Files

Guitars are tricky things to make from scratch. Fortunately for the inexperienced, there are many designers and creators who have released their creations for all to download, mill, and enjoy.

You’ll need to dig a little to find high-quality guitar files, but there is light at the end of the long, winding tunnel in places like this.

Be honest, even if you’re a master of CNC, it’s easy to remember when you were first starting out. To beginners, there’s nothing worse than coming across something you want to build only to find that the files are set out in a way that seems to assume everyone’s an expert.

The clear instructions, illustrated files, and well laid out plans, building your own CNC guitar will be significantly easier than the more obtuse and often overwhelming files of more ‘expert’ posters.

Hints and Tips

Before using your CNC machine to make a guitar, you’re going to need to keep a couple of things in mind.

Double Check All Measurements

First and foremost, remember that guitars are no ordinary CNC project, and need a lot of precise drilling and milling to come out well and working.

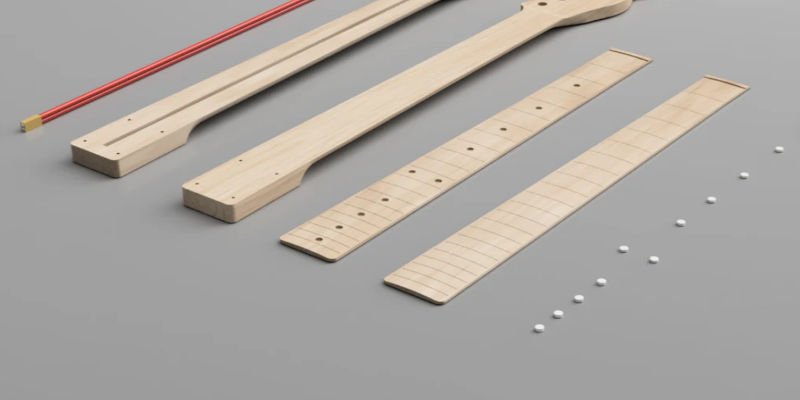

Guitars are more of a project than a simple build, meaning they require different pieces that all need to fit together exactly. From the body to the neck, cavities to contours, you’ll need to be sure that everything lines up, as you’ll have to make each component separately.

This goes double if you’re planning on creating a custom CNC guitar by Frankensteining different designs together.

Know Your CNC Router

If you’re rocking a lower-cost 3018 CNC router, you’ll struggle with carving out the largest parts of your homemade CNC guitar.

Here are a few buyer’s guides we have on larger CNC machines:

Some Parts are Sold Separately

Creating the body is all well and good, and you’re bound to have some fun creating pickguards and headstocks that match your desired look. However, some guitar components simply can’t be created – at least not efficiently – with an average CNC router.

Saddles, capstans, bridges, and strings are a few of the parts you’ll need to buy separately. These come in a variety of sizes and styles, so you’ll want to choose your CNC guitar files before making a final decision on what to get.

Practice First!

Guitars are complicated enough to maintain and play, and building one from scratch with CNC adds a new level of complexity.

Getting used to the different shapes and design quirks will make failed projects less likely. This is important for when you get to using CNC files for working, playable guitars.

Detailed decorative guitars like this will help you get used to the overall shape, and you can even tweak the design in your preferred CAD software to see what will and won’t fit together when it comes to making a guitar you can play. Then you can move to simpler designs with well-written instructions and design notes like this one.

As you become more confident, your projects will improve, and it won’t be long until you’re looking at your own line of custom guitars you can be proud to say you made yourself. Just be sure to hide your copy of ‘Guitar for Dummies’ before showing them off to your friends.

Stay Legal

Making money with CNC guitars is a dream come true for many people. But before you go around selling your creations, you’ll need to make sure you have the legal right to do so. While many creators offer up their designs for free and fair use, some copyright or protect their more unique creations.

Before you go around advertising what you’ve made for sale, be sure you won’t get slapped with a cease and desist for trying!

Other articles you may be interested in:

- DXF files: the best sites to download CNC files

- Laser cut files: the best sites

- The best CNC router software

- The best wood CNC routers

- The best 4×8 CNC routers

- The best wood laser cutters

- What industries CNC routers are used in?