The spindle you use has a significant effect on everything from the run-off to the cutting speed, so choosing the right one for your project and material will result in more accurate, faster CNC work.

For beginners, I’d recommend the Mysweety 500W as a budget-friendly and easy-to-use spindle motor kit. It’s great for hobbyist projects like making signs and home decorations, and personalizing plastic, wood, or leather items.

More advanced users may prefer the improved power and efficiency of the Zhong Hua Jiang 2.2KW, or the extreme precision of the Taishi 3KW – but the trade-off is a higher price tag and steeper learning curve.

|

CNCSourced Rating: |

CNCSourced Rating: |

CNCSourced Rating: |

|

4.5

|

4.9

|

4.7

|

|

N/A

|

$99.00

|

N/A

|

In this guide, I’ll share my hands-on experience with the 3 best spindle motors I’ve used over the past few years. I’ll share exactly what each is best for, along with some top tips to help you make the right decision.

Best CNC Spindles

1. Mysweety 500W CNC Spindle Motor

- Price: Check price on Amazon here

- Cooling: Air

- Collet: ER11

- Speed: up to 12,000 RPM

Pros

Budget-friendly.

Ideal for hobbyists’ projects like making signs and home decorations.

The motor bracket ramp is robust and durable.

Cons

No major drawbacks.

If you’re looking for a budget-friendly spindle that’s quick and easy to get started with for small CNC projects, this Mysweety 500W spindle is a great choice. This is a full spindle kit, complete with an 11V Mach3 speed governor, a 52mm mounted bracket, thirteen ER11 collets, ten V-bit cutters, and four screws.

Capable of engraving at 12,000 RPM and with an accuracy of 0.01-0.03mm, it’s ideal for hobbyist projects like making signs and home decorations, or for personalizing items made of plastic, wood, or leather. The spindle motor bracket ramp is made out of cast aluminum, making for fantastic robustness and durability.

We think it’s always important to see what other CNC enthusiasts say about a product before making a purchase. While we can’t claim to have tested every CNC router spindle motor out there (no one can), over 200 positive reviews mark this as one of the best low-cost spindles on the market, and Mysweety themselves make some of the most popular CNC router kits available right now.

2. Zhong Hua Jiang 2.2KW Motor

- Price: Check price on Amazon here

- Cooling: Water

- Collet: ER20

- Speed: up to 24,000 RPM

Pros

Suited for advanced work.

Works with a variety of different materials.

Powerful and efficient, remaining quiet while in operation.

Cons

Limited customer support.

The Zhong Hua Jiang spindle is a high-quality 2200KW CNC spindle well suited for more advanced CNC work. The increased power of this spindle means you can use it to engrave a wide variety of different materials, including wood, plastic, PVC, copper, brass, and aluminum.

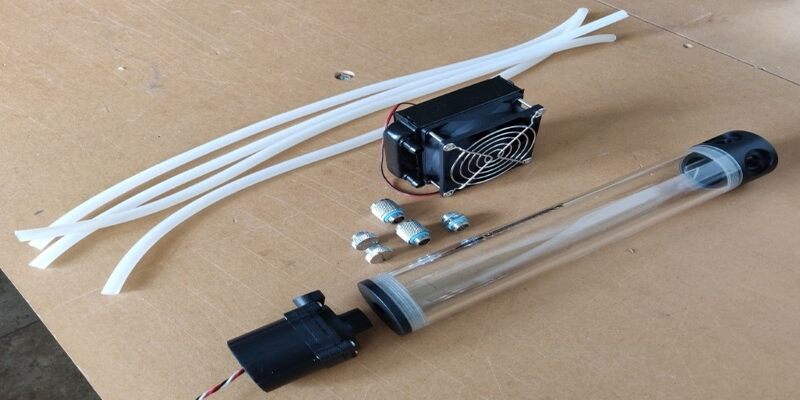

In this CNC router spindle motor kit, you get the 2.2KW water-cooled spindle itself, a 2.2KW VFD inverter, an 80mm clamp mount, thirteen ER20 collets ranging from 1mm to 13mm, a water pump, a 10m hose and 10 bits ranging from 0.8-3mm.

This is a very powerful yet efficient spindle that remains quiet while in operation. It uses advanced dynamic balance technology to reduce noise and improve stability, and it’s also very durable, with upgraded steel bearings that extend the working life, with the manufacturer claiming this spindle can operate for 8 hours a day for two years before needing to be replaced.

It’s also worth noting the less than 0.005mm runout, making this spindle as much as ten times more accurate than standard spindle motors.

You can get up and running quickly and easily, as the VFD comes preinstalled with basic parameters and the kit comes with a pre-soldered aviation wire with a connector and power wire. This is another highly rated spindle among users, with 4.5 stars on Amazon.

3. Taishi 3KW CNC Spindle Motor

- Price: Check price on Amazon here

- Cooling: Water

- Collect: ER20

- Speed: up to 18,000 RPM

Pros

One of the most precise CNC spindles.

Offers enough power to work with hard metals.

Accurate, stable, and easy to assemble.

Cons

Instructions can be difficult to understand for a beginner.

Moving up to 3,000KW, this Taishi CNC mill spindle motor is one of the most popular spindles with this output power.

It’s also the most precise CNC spindle motor we’ve reviewed so far in this guide, with a runout of just 0.003mm, thanks in part to the four high-quality bearings. Unlike the other spindles on our list, this one offers enough power to work with hard metals, including steel.

This is another highly rated CNC router spindle motor kit, totaling a 4.4-star rating on Amazon. CNC enthusiasts have praised various aspects of the spindle, including its accuracy, stability, and easy assembly, as well as Taishi’s customer service.

What is a CNC Spindle?

A CNC spindle motor is the part of the machine that holds the cutting tool, commonly known as the bit. The spindle is usually mounted on the gantry of a CNC router and rotates the bit to cut, drill, or engrave the workpiece, depending on the type of project you’re working on.

This function means the spindle you use has a significant impact on the accuracy, efficiency and power of your CNC machine, as well as the materials you can work with. So, it’s important to choose the right one, particularly if you’re building a DIY CNC router.

Types of CNC Spindles

Although CNC spindles come in a wide variety of shapes and sizes, they can all be broadly separated into three categories – cartridge spindles, self-contained spindles, and fabricated spindles. Let’s take a closer look at each.

Self-Contained

Self-contained spindles are the most widely used among hobbyists due to their ease of use and simple installation. They typically offer speeds of between 10,000 and 30,000 RPM and have power outputs between 500W and 3KW. The spindles we review further down this page are all self-contained.

Cartridge

These are the type most commonly used in vertical machine centers (VMCs) and are generally used in industrial rather than hobbyist settings. They are more complex and are made up of various components, such as a drawbar, angular contact bearings, and a spindle taper.

Fabricated

This type of spindle is present in many older manual milling machines and are built within cast iron housings, making them more difficult to work with and modify. Today, cartridge spindles and self-contained spindles are much more popular than fabricated spindles.

Factors To Consider When Picking a Spindle For Your CNC

When buying a CNC spindle motor, it’s important to carefully weigh up each relevant factor to ensure you make the correct choice. Here’s what to look out for.

AC vs DC

One of the first decisions you need to make is whether to go for an AC (alternating current) or DC (direct current) CNC spindle.

DC spindles are less expensive due to the fact they use cheaper PWM (pulse with modulation) circuits, and they’re most widely used for small-scale hobbyist projects that require low power. As they’re limited to lower voltage levels, a DC spindle is best suited to applications like engraving wood.

On the other hand, an AC CNC spindle motor requires a VFD (variable frequency drive) to regulate speed, which is more expensive. However, they offer considerably more power than a DC spindle. AC spindles are also more flexible and require less maintenance, and as they’re suitable for all CNC applications, they’re generally the more popular choice when price isn’t an issue.

Output power

This is arguably the most important consideration to make when choosing a CNC router spindle, as if you choose a spindle that doesn’t generate enough power for your material or application, you simply won’t get anywhere.

Here’s a look at the applications different powered spindles are best suited for.

Under 1500KW – Machines in this category are best suited for small-scale hobbyist projects. These small spindles are ideal for benchtop routers and are capable of cutting soft materials, as well as engraving wood and plastic.

- The Mysweety 500W CNC Spindle Motor is an ideal starter device

1.5 KW – 3 KW – With this kind of CNC spindle you can cut wood and plastics as well as engrave them. You will struggle to work with hard metals, but spindles with an output power of 2.2 KW and above can cut aluminum. These spindles are generally used on standalone CNC machines.

- Try the Zhong Hua Jiang 2.2KW for a midrange pick

3 KW and above – You need a spindle with an output power of at least 3 KW if you want to work with hard metals and stone. Mild steel processing is possible with 3 KW or similar, though if you want to process stainless steel you’d be looking at 7 KW and above.

- The Taishi 3KW brings professional power into your home workshop

| Spindle Model | Power (KiloWatts) |

|---|---|

| Mysweety 500W CNC Spindle Motor | 0.5 |

| Zhong Hua Jiang 2.2KW | 2.2 |

| Taishi 3KW | 3 |

Air cooling or water cooling

All spindles come with a cooling mechanism to help prevent overheating and extend tool life, the two options being air cooling and water cooling. The water cooling technique is more effective and longer lasting, meaning it’s preferred for high power jobs, but it also has its downsides.

For starters, water-cooled spindles are the most expensive. On top of that, they require a variety of equipment, such as a pump and storage tanks, and they can be less effective in cold environments if the water freezes. In contrast, air-cooled spindles are more simple to use, require less space, and generate higher torque, but are not as effective in terms of cooling.

CNC Spindle Collet Size

The collet is the part on the end of a CNC spindle’s shaft that actually holds the bit in place and determines the size of the bits you can use. Larger collets can hold larger bits but they’re also heavier, so they should reflect the size of the CNC machine you’re working with.

There are six different collet sizes ranging from ER11 to ER40, although for hobbyist CNC work you’re unlikely to ever use one above ER20. Here’s a look at how collet sizes vary in CNC router spindles:

| ER Collet | Length | Diameter | Clamping Range |

|---|---|---|---|

| ER-11 | 18 mm | 11.5 mm | 0.5—7 mm |

| ER-16 | 27.5 mm | 17 mm | 0.5—9 mm |

| ER-20 | 31.5 mm | 21 mm | 1—13 mm |

| ER-25 | 34 mm | 26 mm | 1—16 mm |

Spindle build

You want to go for well-made, durable CNC spindles, as this will ensure high performance over continuous use and extend the tooling life. Look for ones made of cast metal that are optimized for robustness. Aluminum spindles are suitable for working with wood, plastics and similar materials, though if you’re working with hard metals you’ll want one that’s made from steel or cast iron.

A spindle’s bearings can also have an impact on its durability. The bearings heat up during work, so you ideally want a spindle with bearings made of ceramic of a similar heat resistant material to help improve the tool’s durability

Runout

The bearings also have a significant impact on the runout of a spindle, which is the deflection between the shaft and central axis. The more runout, the less precise cuts your machine will make. Manufacturers typically display this in millimeters, so you can easily pick a spindle that offers you the level of accuracy you need. Runout can vary a fair bit from spindle to spindle, but you should look for ones that offer a runout of no more than 0.005mm.

Speed & torque

The speed a spindle works out is measured in RPM (revolutions per minute). Cheaper ones typically offer speeds up to 12,00 0RPM, while higher quality spindles can go up to 24,000. Lower speeds between 6,000 and 15,000 are best for hard materials, while 24,000 RPM is ideal for softer materials.

You need to also consider the torque, which is the force a spindle exerts and determines the hardness of the materials you can work with. Naturally, higher torque spindles cost more than low torque ones.

| Product Name | Speed (RPM) |

|---|---|

| Mysweety 500W | up to 12,000 |

| Zhong Hua Jiang 2.2KW | up to 24,000 |

| Taishi 3KW | up to 18,000 |

Size

We’ve already touched on it, but as well as the power a spindle can generate, you need to consider its physical size to ensure it’ll match your CNC machine. For example, you’re not going to be able to pair a 7000KW spindle motor with a small benchtop CNC router.

Price

Last but certainly not least, choose spindles that offer good value for money within your budget. Spindles can vary a lot in price, from under $50 to more than $500 – we take a look at spindles within different price ranges below to give you an idea of what to expect.

Related posts: