In this article, we’ll cover all the best CNC routers for signmaking – for DIYers, small business owners, and hobbyists looking to make and sell signs.

|

CNCSourced Rating: |

CNCSourced Rating: |

CNCSourced Rating: |

|

4.3

|

4.5

|

4.7

|

|

$1198

|

$649.00

|

$2299

|

|

Material options:

Metal, wood, plastic, foam

|

Material options:

Wood, plastic

|

Material options:

Wood, plastic, metal

|

|

Working Area:

4’ x 8’ (48” x 96”)

|

Working Area:

15.7” x 15.7”

|

Working Area:

29.5" x 29.5" x 4.5"

|

|

Speed:

10,000-30,000 RPM

|

Speed:

20,000 RPM

|

Speed:

10,000-30,000 RPM

|

|

At a glance:

A large-format router that’s robust enough to tackle metal and doubles as a laser cutter.

|

At a glance:

A low-cost, smaller, low-power CNC router that can handle your needs as a beginner sign maker.

|

At a glance:

Excellent CNC for small businesses

|

|

|

We’ll only look at options that are good for making signs for DIYers, small business owners, and hobbyists, and we have not picked any industrial machines because we’re focusing this article towards smaller businesses.

Quick Overview

- MakerMade M2: Best For Huge Signs

- BobsCNC Evolution 4

- Shapeoko 4 6L

- SainSmart’s Genmitsu 4040-Pro: Best Budget Pick

- Inventables X-Carve: Premium Pick

- SainSmart’s Genmitsu 3018-Pro

The Best CNC Routers for Sign-Making

Entry Level CNCs

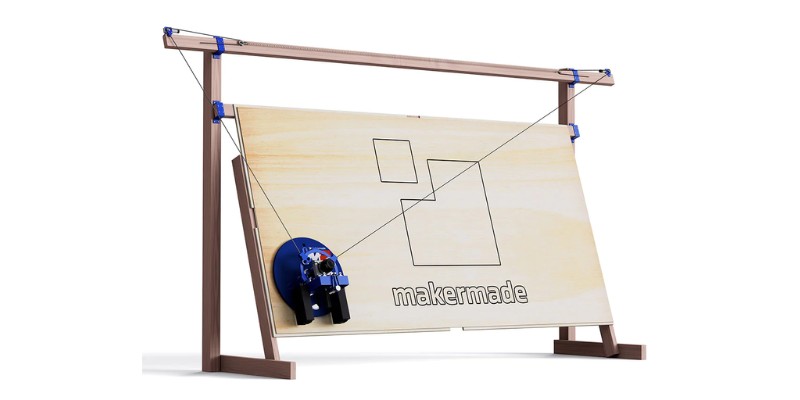

1. MakerMade M2 — Best CNC for Huge Signs

- Price: Check latest price at MakerMade here / Amazon here

- Material options: Metal, wood, plastic, foam

- Working area: 4’x8’ (48”x96”)

- Precision: 1,000 micron (0.039”)

- Speed: 10,000-30,000 RPM

- At a glance: A large-format router that’s robust enough to tackle metal and doubles as a laser cutter.

Pros

Can cut large signs

No need to cut your sign frames elsewhere (Can cut many small sign frames out of a 4 by 8 sheet)

Upright design (occupies a small area)

Price

Cons

Inaccurate – can’t engrave accuracy-demanding fonts

Must buy router and frame separately

Longer assembly time

The MakerMade M2 outcompetes every other CNC router on our list when it comes to size. It offers a massive 4 x 8 foot cutting area which allows you to make some massive signs.

The price is very reasonable, which is largely due to its construction. It’s a wall-mounted router rather than an upright table, making it both more affordable to produce (and thus cheaper for you to buy), as well as making it much easier to fit in your workshop! Unless you have an enormous workshop, finding the space for a 4×8 CNC is not easy.

As far as precision, the M2 falls short. It cuts with up to 1mm accuracy, but that’s it. If you think about it, it makes sense: it’s so huge that naturally, you lose some resolution on your cuts. This isn’t ideal for very precise signs with intricate letters, but with sanding and post-processing, you’ll still achieve good results cutting sign frames or carving large letters.

Also, the MakerMade M2 is more accurate in the top corners, so you can make separate letters and graphics for hand lettering your wooden signs.

This CNC router doesn’t come with a router, but it has a 71mm clamp that’s firmly attached. MakerMade says that a Makita RT0700CX works really well, which has a 1/4” collet and a variable speed from 10,000 to 30,000 RPM.

The framework features powder-coated steel, which is very sturdy. The motors are also overengineered, durable, and strong. They are chain-driven, which allows the router to cut such a large area on the wall-mounted gantry.

You can upgrade this machine to be a laser cutter as well. The laser cutter module sells for $500 through MakerMade, and the installation couldn’t be easier.

Speaking of installation, putting together this router table is, unfortunately, pretty difficult. Luckily there’s a lot of online support to help you through the process.

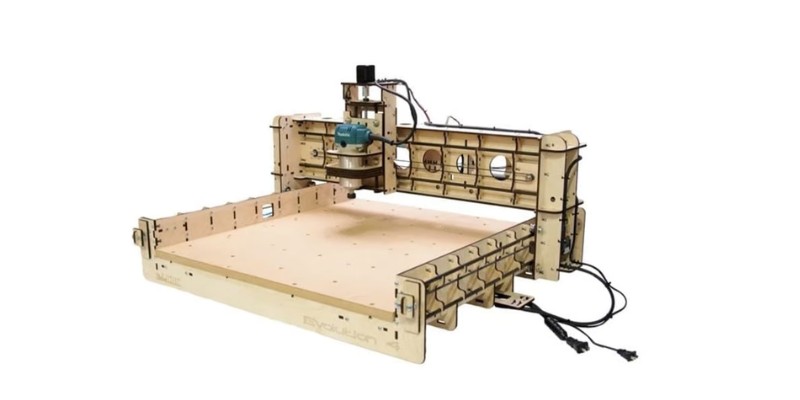

2. BobsCNC Evolution 4 — Best for Hobbyists

- Price: Check latest price at Amazon here

- Material options: Wood

- Working area: 24”x24”

- Precision: 13 microns (0.0005”)

- Speed: 10,000-30,000 RPM

- At a glance: Tackle larger DIY wooden signs with ease on this CNC router.

Pros

Engraves wood signs

Affordable price

Cons

Rigidity – compromise cutting depth or feed rate

Cuts only soft materials (wood, MDF, PVC)

Inaccurate under load, especially near the sides

Very heavy for what it can tackle

Long assembly

No ACM or aluminum signs

The Evolution 4 from BobsCNC looks like a Trojan Horse because the whole machine uses 5-ply Baltic birch and MDF. This is what happens when you task a DIYer to make their own CNC router! But, by making out of wood, BobsCNC are able to price this excellent CNC router very affordably.

The Evolution 4 is a 3-axis CNC router that can handle boards up to 2.25” thick. It also includes wooden work holding features that you can thread down to secure your wood in place before cutting.

We should mention that this CNC router is only approved to work on cutting wood – we explain in our best CNC routers for metal cutting article that while it can technically work on aluminum, even the BobsCNC team themselves don’t recommend it. The framework simply isn’t sturdy enough to handle routing metal signs.

Plus, the lack of rigidity can cause huge inaccuracies. You’ll have to cut wooden signs only and at small feed rates. Otherwise, you’ll put too much pressure on the machine, it will bend, and result in very imprecise cuts.

Luckily, the 24” x 24” working area allows you to make decently sized wooden signs with pretty good precision.

The process of building the Evolution 4 isn’t so easy. It takes 2+ days to complete and involves a lot of fasteners and setup.

The oversized motors are powerful, allowing for a huge speed range. The downside is that you’ll notice a lot of wobbling while you run it, since the frame is all wooden.

It works with Windows, Linux, or Raspberry Pi devices since it uses an Arduino controller to run the program. All of the associated software is free and pretty easy to set up.

The router comes with a 1/4” collet (it’s actually a Makita collet), allowing you to use any stock straight, vee, or rounded bits that have either a 1/8” or 1/4” shaft.

The Evolution series of machines, which stand out for their laser-cut wooden frames and somewhat unusual designs, with the Evo 4 being the best in the line, are possibly the most well-known products from BobsCNC.

Effective Small Business Machines

3. Shapeoko 4 6L — Best for Small Businesses

- Price: $2,300 — Available at Matterhackers here

- Material options: Wood, plastic, soft metal

- Working area: 33”x33”

- Precision: 13 micron (0.0005”)

- Speed: 12,000-30,000 RPM

- At a glance: A great option with versatility and a large cutting area for any small business.

Pros

Can cut and engrave signs rather accurately

Can cut thin ACM, aluminum, anodized aluminum, and acrylic signs

Can do channel letter fabrication

Cons

More maintenance than average beginner CNCs

The Shapeoko 4 comes as a Standard, XL, or 6L. If you’re making signs on this CNC router, then you’ll need the 6L, which comes with a massive 33” x 33” working area. It’s a great addition to any small business or side hustle.

It’s a 3-axis CNC router that can handle wood, plastics, and soft metals. The optional T-slot hybrid table (included in the $2,300 option) makes work holding even easier – and you can install a number of clamps to ensure your parts don’t move.

This tool is compatible with a 65mm diameter router and allows for operation at 110V. Shapeoko suggests using the Carbide 3D Compact Router (C3D-ROUTER-120), which has a 1/4” collet.

4. SainSmart’s Genmitsu 4040-Pro — Best for Beginners

- Price: Check latest price at Sainsmart here / Amazon here

- Material options: Wood, plastic

- Working area: 15.7”x15.7”

- Speed: 20,000 RPM

- At a glance: A low-cost, smaller, low-power CNC router that can handle your needs as a beginner sign maker.

Pros

Price

Cut and engrave wood signs

Cut acrylic and hardened PVC

Easy to assemble

Cons

Medium-sized signs only

Beginner-level – not much room to grow

The Genmitsu 4040-Pro from SainSmart is one of the best options for beginners. To start, assembly of this CNC router only takes about 15 minutes: the gantry assembles with a dozen bolts, then it takes a few more to attach the base.

The frame itself is very sturdy. It’s made out of aluminum, and the internals feature high-strength steel tubing with a lead screw motion drive. This means you can accurately cut and engrave all sorts of wooden signs, as well as emboss texts and graphics. You can even cut hardened PVC.

The work area doesn’t allow for massive projects, but you can handle entry-level sign-making without problems. The user interface has a power button and e-stop, making operation even simpler.

There are a lot of extra accessories you can add. The biggest one is a compatible laser module, turning your CNC router into a 10W laser cutter to make signs. The other accessories, like their clamps, dust shoe, and tools, will make your life a little easier while you make signs for your customers.

It has a 1/8” collet, which is smaller than others on this list. It means that you can’t tackle bigger projects or work on metal, but you can do plenty with this setup. In reality, the Genmitsu 4040-Pro is plenty for any small-scale side hustler or DIYer.

5. X-Carve 1000mm — Simplest to Use

- Price: $2,300 — Available at Matterhackers here

- Material options: Wood, plastic, and aluminum

- Working area: 29.5”x29.5”

- Speed: 10,000-30,000 RPM

- At a glance: A very simple CNC router that is easy to set up, start a project, and run.

Pros

Can carve and engrave wooden signs

Can cut thin ACM, aluminum, anodized aluminum, and acrylic signs

Can do channel letter fabrication

Cons

May need to change its Makita router if using it for long hours

The X-Carve is a well-built CNC router that can keep up with your small business or DIY projects. The working area is pretty average for the market, but this machine is all about being easy to use.

Out of the box, the X-Carve has everything you need: it comes with a Makita RT0701C router, dust collector, clamps, z-probe, and Easel Pro software. Some assembly is needed, but then it’s ready to go, with no need to buy extra accessories.

When you want to run a project, you can open Easel Pro and simply draw pictures on the screen (a lot like Microsoft Paint). You can send those pictures to your CNC router, and it will start cutting.

Why is this great? You can make custom signs directly on this program and then watch your machine get to work. It can handle wood, plastic, and aluminum, which is a great assortment for making signs.

Inventables also has impressive support if you run into trouble. With an X-Carve, you have readily accessible 24/7 support for life, a 2-year warranty, and simple returns in the first month if you don’t like the machine for any reason.

Just in case you need to cut thicker wood that a laser isn't ideal for - here's our top CNC router pick.

6. SainSmart’s Genmitsu 3018-Pro — Best Budget (for Smaller Signs)

- Price: Check latest price at SainSmart here / Amazon here

- Material options: Wood, plastic

- Working area: 11.8”x7”

- Speed: 20,000 RPM

- At a glance: A budget-friendly, small CNC router that can easily handle smaller signs without breaking the bank.

Pros

Extremely cheap

Cuts and engraves small signs rather accurately

Cons

Small signs only

Must cut the sign frames with a different machine

Another CNC router from SainSmart is the Genmitsu 3018-Pro. There are two differences between this tool and the 4040-Pro we mentioned earlier: the price, and the size.

The price is under $200, which is unheard of. But, with the 300 x 180 mm work area (where the 3018 name comes from), it’s naturally only best for CNC cutting small signs – and I recommend something larger if you have the budget. The 300 x 180 mm maximum cutting area, to put in perspective, is slightly smaller than a piece of A4 printer paper.

Still, this machine over-delivers based on how inexpensive it is. It has the same 1/8” collet and offers an optional laser module to turn the router into a 5.5W laser cutter. A y-axis extension kit will expand the cutting area to 11.8” x 12.6” for another $60.

This machine is perfect for any DIYer who wants to get a taste for CNC signs before dropping a lot of money. It has great versatility and functionality, and the price tag is very attractive. It’s not a good option if you plan on making larger signs in the future however, or if you want to work on metal signs (people technically HAVE managed to cut aluminum with it online, but we really don’t recommend using it for this).

Keep in mind, you’ll have to do some assembly to put it together, and it doesn’t include a router. Even so, you could buy all the optional accessories and upgrades, add a nice router, and buy a laser module, and still spend less than $500 altogether.

The 3018 PRO from Sainsmart has a sizable build surface that can handle even large wood projects and is efficiently fastened down thanks to its sturdy aluminum frame.

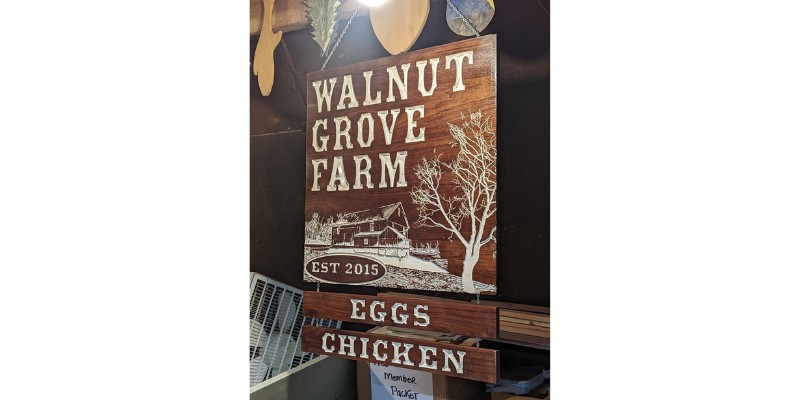

How Do CNCs Make Signs?

The easiest way to make signs using a CNC is to create wooden signs. Most CNCs can easily do this. They can cut and engrave the sign or create embossed texts in wooden signs.

However, there are many methods of sign-making, and therefore many different ways CNCs can make signs. In fact, not all CNCs can perform sign-making tasks – we’ll explain this in more detail further on.

Therefore, you should consider what type of sign you want to make: this helps figure out which CNC is best for you.

Types of Signs You Can CNC

Wooden signs might be popular on Etsy, but in industry, other signs are more common. So, here is a list of different ways CNCs can make (or help make) signs:

- Wooden signs: the CNC can carve the sign directly in wood (or MDF, Bamboo, etc). There are also methods of coloring to create contrast.

- Hand lettering wood: the CNC carves separate letters out of wood for hand lettering.

- ACM signs: the CNC (or laser) cuts the required ACM size. The CNC could also cut custom-shaped signs out of ACM sheets. Then, it drills holes in the ACM for mounting. Additionally, the CNC can round the cut edges with a bullnose endmill if the customer is willing to pay more. However, making ACM signs also requires printing or painting.

- Channel letter fabrication: the CNC (or laser) cuts returns and backs from aluminum sheets. The CNC (or laser) will also cut the face out of aluminum for opaque signs, and out of acrylic for LED-illuminated signs. CNC is far superior to hand-cutting since hand-cut letters have void spaces, which can result in water entering and destroying the light.

- Hardened PVC signs: hardened PVC is an excellent surface for creating channel letters. CNCs can easily cut hardened PVC, especially since lasers aren’t suitable for cutting these surfaces.

- Aluminum signs: CNCs or lasers can cut custom aluminum signs. You can CNC-engrave, paint, or use printing methods on aluminum signs.

- Anodized aluminum signs: however, laser engraving anodized aluminum signs is faster. So, it’s best to have a CNC for cutting, and a laser for engraving. Alternatively, you can get a very powerful laser (several hundred watts) that can cut and engrave.

- Acrylic signs: CNCs can cut acrylic signs, and also cut text or graphics out of contrasting acrylic. However, achieving an excellent acrylic surface finish is more difficult on a CNC router than with a laser, though CNCs are easier to cut thick acrylic with.

- Colorbond signs: though they’re falling in popularity, CNCs can cut shapes of our colorbond. You’ll still need printing methods or painting to finish the sign.

It is very important to remember therefore, that since there are so many methods and types of signs, not all CNCs work for all types.

So, understand which types of sign you plan to cut, and then choose between CNCs capable of this. For example, not all CNC routers can cut tough aluminum signs.

To help you with this, it’s helpful to think of three distinct categories:

- Entry-level: These budget CNC routers are not very precise. However, they can cut wood signs and cut letters out of wood panels for hand lettering. They can also cut hardened PVC for channel letters.

- Effective small business machines: Accurate enough to carve engravings or create embossings in MDF or wooden sheets. Some of these CNCs may also cut acrylic and 3mm ACM and aluminum signs, and engrave anodized aluminum signs. However, they can’t cut thicker metal signs.

- Industrial CNC machines: These CNCs can cut all aluminum and colorbond signs. These CNCs are also more expensive.

We’ll be focusing on entry-level, and effective small business CNCs, in this article.

What Makes a CNC Good for Sign Making?

Whether you’re making a sign as a hobby, a gift, or you run a small business — here are the things in a CNC that affect sign-making:

Precision

The precision of your CNC tool will determine how accurate each cut is on your chosen model. For example, if you draw a 1” x 1” square, the precision of your router tells you how close each dimension will be to 1.0”.

Imprecise entry-level CNCs have trouble even engraving wooden signs with fonts that have tight tolerances.

Rigidity

Rigidity and power determine whether we consider a CNC level 1 or level 3. But having higher power without rigidity is useless, and therefore rigidity affects a CNC’s power.

Rigidity also determines what materials you can cut, and it’s one of the most important factors and specs in a CNC router.

Cutting Area

The cutting area refers to how large of a rectangle you can cut. Obviously, a larger cutting area means that you can cut larger signs. For this sign-making CNC router comparison, I have only considered larger machines that can handle sign-sized pieces of wood.

Overall Versatility

If your sign-making CNC machine is more versatile, it can handle a wider breadth of projects such as some CNC machines for guitars. The most versatile machines have a laser attachment, can work on metal, and feature a large cutting area. These CNCs have everything they need to handle unique customer orders and projects.

If it Requires Additional Tooling

Oddly enough, some CNC routers don’t come with a router. You may have to buy extra accessories to successfully cut a piece of wood. This ups your total investment to start making signs, so it’s worth factoring into your calculations.

Material Compatibility

The materials your CNC router can handle depends on the router’s power and size, plus the rigidity of the router table.

All of the routers on our list can handle wood, some can handle acrylic (plastic), and fewer can handle metal. If your project demands cutting metal, then you have no choice. Picking the wrong router means that you can’t satisfy your customers.

Your CNC Router’s RPM

The router’s speed will determine how smooth the cut is, how much sanding you’ll need to do after, and how quickly you finish the sign.

Having a variable-speed router opens the door for more projects, different material thicknesses, and more refinished finishes on each project.

User Interface for Designing and Cutting Signs

What about some added creature comforts? Some CNC routers come with software that makes it even easier to design and cut signs. Other machines have simple buttons to start and stop the project. Features like this aren’t necessarily deal-breakers, but it definitely makes your sign-making business easier.

A great example of excellent software UI is Snapmaker Luban. It made it easy to cut patterns in wood on my Snapmaker 2.0 A350. Easel is also simple to use.

Number of Axes

Fancier CNC machines have a 4th axis which allows the cutting head to physically rotate while it moves. The 4th axis is great for sculpting, but it doesn’t help much in sign-making. All of the CNC routers on our list have 3 axes.

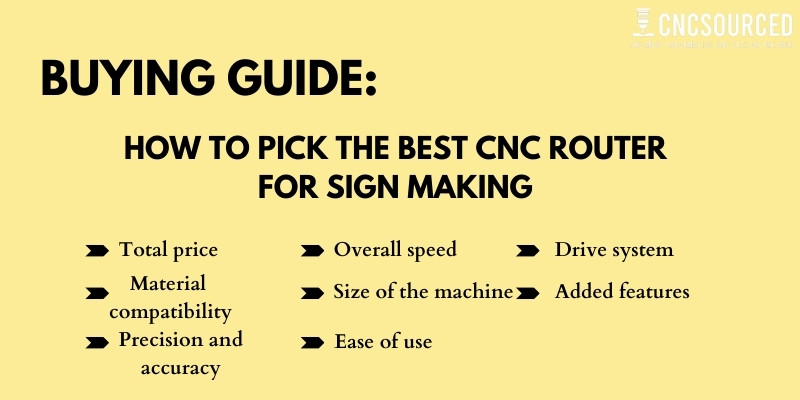

Buying Guide — How to Pick the Best CNC Router for Sign Making

Here are some considerations to think about when deciding on a CNC router table for signs.

- Total price. You just saw a pretty wide range of prices in the CNCs we recommended. Make sure your chosen CNC router meets your budget, and has the size and power to cut the signs you want to make.

- Material compatibility. Ensure the machine can handle the material you need to use. If you’re making wooden signs, then any option on our list is appropriate.

- Precision and accuracy. A precise machine makes your signs look better. However, don’t conflate precision with repeatability – they’re not the same.

- Overall speed. Faster machines translate to faster project completion and better aesthetics on your signs. Ideally, you should pick an option that has a variable-speed router.

- Size of the machine. The size of the machine will determine how large of a sign you can make, but it also determines whether or not the router will fit in your woodshop or shed. Ensure your CNC router is large enough to handle your projects, while still fitting in your room.

- Ease of use. We always prefer working on easier machines. Some of the tools on our list have added features to make the CNC router even easier to use, and the X-Carve and Easel workflow is one of the most user-friendly, in my opinion.

- Drive system. A chain-drive motor is more robust than a belt-driven motor. However, a screw-motion drive is robust and more accurate. The drive system will play into the accuracy and speed of the CNC router.

- Added features. Added features can turn your router into a laser engraver, clean up sawdust, and protect you. Check for these added features before checking out.

Alternatives to CNC Routers for Making Signs

You don’t necessarily need to use a CNC router if you want to make a sign. You can also use a laser cutter, manual (hand) router, plasma cutter, or even a waterjet machine.

All of these, with the exception of manual cutting, can be CNC controlled, but they come with different price tags, advantages and disadvantages.

What Is the Best CNC Bit for Lettering?

To make small and precise CNC lettering, use a 30° V-bit.

For fast lettering, a straight bit will work.

For rounded and 3-dimensional lettering, try a rounded bit. Make sure the shank size fits your collet, or else you can’t use the bit — for instance, a 1/4” bit fits in a 1/4” collet, but not a 1/8” collet.

Which Wood Is Best for CNC Sign Making?

The wood choice for your CNC sign making will depend on your preference. Cedar is popular because it has a nice color and it’s easy to work with. Pine is softer and easier to cut, but the color is lighter and doesn’t pop as much.

You may also use hardwoods like maple or walnut that have strong grains, a beautiful aesthetic, and are highly durable.

What Router Bit Do I Use to Make Signs?

When you own your own CNC router, you can use a wide range of router bits to make your signs. Straight bits make high-contrast lettering with flat bottoms. Rounded bits will give a radius to your design, making it pop out.

Any type of V-bit offers good precision for lettering, but it requires specialized CAM features. Carving bits create very small profiles for precise lines. Also, holding and chamfer bits can add a nice-looking profile to the outside of your signs.

I recommend you buy an assortment of bits and try them on some scrap wood to see what you like best.

How Do You Paint CNC Wood Signs?

After making a wooden CNC sign, you should start with a sealer and sand between each coat to prevent dust buildup. Paint the face of the sign with a paint roller. Doing this will cause the cut lettering to remain wood colored.

To paint the cut letters, you can use masking tape to cover the painted area (which has now dried) and use spray paint to coat the surface. Use a damp towel or sponge to wipe the surface to get rid of the secondary color, leaving a sharp contrast between the sign’s face and letters.

What Is the Best CNC Sign Making Software?

The CNC software we highly recommend using is Easel, Carveco, or Inkscape. These are great options for making signs on a CNC router. They are either free or low-cost, depending on which you choose.

How Do You Make Signs with A CNC Router?

You can make perfect signs on your CNC router by starting with a good design, preparing and clamping your material appropriately, double-checking your settings, using the right routing bit, and painting the sign when it’s done.

Is It Easy to Start A CNC Sign-Making Business?

Starting a CNC sign-making business is easy, as long as you’re ready to start working. You’ll have to gather the right equipment, go through hours of training, pick the niche you want to target, then start marketing your business. Once established, you should get the right permits and licenses needed to protect your business legally.

You can technically start almost right away, selling on Etsy, or even eBay, Facebook groups, and other places. But for better branding, you can also start your own website and store.

What to Do Next

Now that you have the right CNC router, you’re ready to get started. Grab some scrap material and start practicing!

Spending time learning your machine and software will save you time in the future when you have to make signs for customers, family, or yourself.