In this article, we’ll discuss two main types of machines: CNC routers (which can cut soft metals like aluminum) and CNC metal mills (designed to handle harder metals like steel, stainless steel, brass, titanium, magnesium, and more.)

I’ll step you through my hands-on experience with each machine (comparing key features like power, work area, and ease of use) so you can make the right choice for your project.

|

CNCSourced Rating: |

CNCSourced Rating: |

CNCSourced Rating: |

|

4.3

|

4.0

|

4.0

|

|

$269.00

|

$2300

|

$2299

|

|

|

|

CNCSourced Recommends

The best CNC routers for aluminum:

- Sainsmart Genmitsu 3018 PROver — Our top budget pick

- Inventables X-Carve — For large metal projects

- Carbide 3D Shapeoko 4 XXL — The professional choice

The best metal CNC machines for aluminum, steel, titanium & more:

- Taig 2019CNC Micro Mill — Cheapest CNC mill for tougher metals

- MillRight CNC Power Route XL — Large metal machine with high torque

- Tormach PCNC 440 CNC Mill — Powerful desktop option

- Laguna Swift 4×8 CNC Router — The premium industrial choice

The Best CNC Routers for Aluminum

1. Sainsmart Genmitsu 3018 PROver / Pro – Best Budget Pick

- 3018 PROVer — Available on Sainsmart Store here / Amazon here

- 3018 PRO — Available on Sainsmart Store here / Amazon here

- Work Area: 300 x 180 x 45mm

- Max Spindle Speed: PROVer: 10,000 RPM, PRO: 9,000 RPM

- Compatible Materials: Soft metals like aluminum, plastics, and wood

It's cheap, and not super powerful, but with a few upgrades it can cut into thin aluminum.

Pros

Strong and sturdy.

A very versatile machine.

Comes with over-voltage protection, over-current protection, and short-circuit protection making it very safe.

Cons

Not ideal for aluminum.

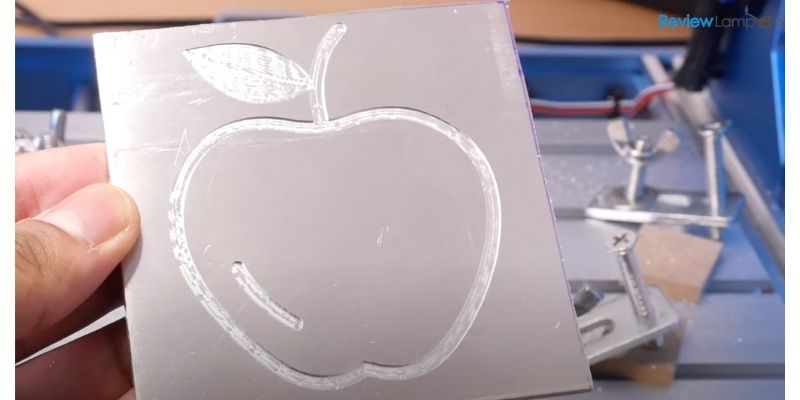

Sainsmart’s Genmitsu 3018 Pro and PROVer range are some of the most popular of Arduino-powered low-cost CNC routers. While they’re primarily designed for wood and acrylic carving, they can also be used for copper PCB board cutting and soft aluminum cutting — as long as you don’t want to cut too deep.

Upgraded on the original 3018 Pro, the PROVer mini CNC metal router comes almost fully pre-assembled, cutting assembly time from a few hours with the 3018 Pro, to just 15 minutes. This is perhaps if you’re a beginner, or busy, so you can get making almost immediately.

The PROver is also a very strong and sturdy mini metal CNC machine, with an all-aluminum body and a sharp oxide-blue finish. This provides great stability and allows you to work with a wide range of materials, including soft metals like aluminum, plastics, and wood.

The sides are reinforced with acrylic panels to prevent any chips from flying off, both good for health and safety, and keeping your workspace cleaner.

The PROVer comes with a default 1/8″ ER-11 collet, which you can upgrade, for example to a 1/4″ ER-11. However, be wary of the strain this adds to the less powerful spindle, and the resulting effects it could have on its lifespan.

With the 3018 PROVer you also get an optional laser engraver module, which is handy if you fancy engraving and save space in your work area, as well as money, with two machines in one. Sainsmart machines are almost endlessly upgradeable, so you can tweak it to make it yours. We recommend buying the end mill kit available here.

While not ideal for aluminum (in fact, it’s far from it), if you’re playing around with a couple small aluminum pieces for your own fun, the Sainsmart 3018 PROVer can work. But, if you’re more serious about CNC carving metal like aluminum, consider going for a more professional metal CNC cutter.

Consider upgrading the machine’s spindle, to a Dremel 3000 tool head or similar, as well as the stepper motors — and you might also consider the power supply and board to avoid having to connect it to a laptop all the time, and risk getting aluminum chips on it.

The full recommended settings for CNC cutting aluminum can be found in this video:

Overall, while we don’t recommend it for professional CNC metal uses, it is a good small machine for metal — if you’re careful and consider the upgrades.

2. Inventables X-Carve 1000mm — A Reliable Router

- Price: $2,599 — Available at Matterhackers here

- Work area: 29.5 x 29.5 x 4.5 inches

- Max Spindle Speed: 30,000 RPM

- Material Compatibility: Aluminum, carves PCBs, as well as standard softer materials like MDF, foam, cork, acrylic, and much more.

Just in case you need to cut thicker wood that a laser isn't ideal for - here's our top CNC router pick.

Pros

Comes with a free Easel Pro subscription.

Good quality parts and a reliable machine for the money.

Can cut a wide range of materials as well as aluminum.

Cons

The setup process will be difficult for beginners.

Inventables manufacture the X-Carve range, some of the highest-quality desktop CNC mills around, opening up options for CNC milling large aluminum sheets with its large work area. You may also have used Easel before — it’s probably the most accessible CNC CAD-CAM software out there for beginners, and Inventables offer free Easel Pro subscriptions with their machines.

On Inventables’ material list for the X-Carve, they list 6061 aluminum as a cuttable material. Users of the X-Carve 1000mm metal CNC mill have used it without any Z-axis upgrades to cut aluminum without much issue.

For your money, you get quality parts and a reliable machine that requires little maintenance and upkeep — perfect as a CNC machine for small business. The DeWalt 611 spindle and mount, 1,000 mm wasteboard, dust control system, and carving bit super pack make for effective carving and cutting. The wide, thick-walled gantry aids consistent carving, as do the molded belt clips and other features.

As well as aluminum, this metal CNC mill cuts and carves PCBs, as well as standard softer materials like MDF, foam, cork, acrylic, and much more. It’s a small business hero, and can cut up to 4.5-inches deep for accurate and beautiful 2.5D carving for signs and topographical map projects, and a variety of other popular designs.

Inventables have an older video of an X-Carve model CNC milling aluminum to make an LED ring for a spindle here:

3. Carbide 3D Shapeoko 4 XXL – Great for Small Businesses

- Price: $2,300 — Available at Matterhackers here

- Work Area: 33″ x 17.5″ x 4″

- Max Spindle Speed: 30,000 RPM

- Material Compatibility: Soft metals such as aluminum, wood, and brass

One of the most well-made CNC routers, ideal for cutting tougher woods and metals like aluminum.

Pros

Excellent mid-range option for small businesses to machine aluminum and other material parts.

Has a variety of different feeds and speed settings.

Can set it up and have it working in a matter of hours.

Cons

Does not include a dust collection plate.

Similar in price to the Inventables X-Carve, both the Shapeoko range and Inventables’ aluminum CNC machines are excellent mid-range options for small businesses to machine aluminum and other material parts.

In fact, Carbide 3D have a variety of different feeds and speeds settings for various end mills within Carbide Create — their CAD-CAM software — making it easier than ever to select your profile and get straight to cutting aluminum.

It is a DIY CNC kit, so it’ll take time to set up, and a certain amount of technical DIY skill is required. The Shapeoko 4 comes with some serious improvements over the previous Shapeoko 3 and Pro models, such as a 65mm router mount, more durable belts, leadscrew-driven z-axis, and more.

It’s great for carving, and comes with a dust boot system to keep your work area clean and easily visible during work. And while the Shapeoko 4 XXL is the biggest model — a whopping 33″ x 33″ x 4″ — you can save money for opting for the smaller standard Shapeoko 4, or Shapeoko 4 XL.

You’ll need to cater for lubrication and chip clearing, however. Generally, focus on slower plunge rates, shallower depth of cuts with higher feed rates, and single flute endmills — as with all the metal CNC routers we recommend. Carbide 3D also recommends coated end mills.

Makers within the Carbide community have experienced much success cutting aluminum for various business projects. For example, this maker describes how they Carbide Create to design metal CNC projects, pocket toolpaths and feeds and speeds tweaking, and various other specific settings to get great results.

Here’s a video by Carbide 3D explaining feeds and speeds in-depth for the Shapeoko 3. While the Shapeoko 4 is newer and upgraded, it still contains relevant and helpful info for CNC machining aluminum with the Shapeoko 4 XL or XXL:

The Shapeoko 4 comes with everything you need to get a small manufacturing business off the ground, with dust boot system, Carbide Create CAD-CAM software and Carbide Motion control software, T-slot hybrid table and M6 T-nuts for affixing your projects.

Overall, it should be considered for best CNC router for aluminum — but for more professional metal CNC, consider a home CNC milling machine.

The Best Metal CNC Mills & Machines For Stonger Metals

These more heavy-duty metal CNC machines have more torque and power, and if you’re thinking about getting into metal CNC fabrication, consider one of these more professional options.

These are better for metals like:

- Steel

- Stainless Steel

- Titanium

- Brass

- Magnesium

4. Taig 2019 CNC Micro Mill — Powerful Metal Milling on a Budget

- Price: $2,495 ($2,995 for 2019DSLS version)

- Work Area: 12” x 5.5” x 6”

- Max Spindle Speed: 10,000 RPM

- Material Compatibility: Aluminum and titanium

Pros

One of the cheapest CNC mills for metal you can buy.

Powerful machine with 30 inch/min travel speeds.

Integrated with Mach3.

Cons

The work area is small.

Taig’s micro CNC mill, and one of the cheapest CNC mills for metal you can buy, the 2019 CNC opens up your metal milling possibilities, for the same price as the Inventables X-Carve or Shapeoko 4.

However, you sacrifice work area with this torque upgrade. With a far smaller travel area, you can only mill small metal parts, but for any specialists in metal CNC milling, this may be perfect as generally metal parts are smaller than larger hobbyist wood or plastic parts.

Taig promotes the 2019 CNC’s advanced bilevel chopper drive technology, which, combined with their new NEMA 23 stepper motors with 200 oz holding torque, makes for a powerful machine with 30 inch/min travel speeds. The steel and aluminum engineered structural design makes for sturdy, durable milling, and along with aluminum and titanium cutting, the Taig CNC can cut steel at 1/8” depth with a 1/8” end mill on mild steel — very impressive for the low price.

All three axes use lead screws, though Taig has more premium models with ball screws if that’s a sticking point, such as the 5019CNC. If you’ve used Mach3 CNC software before then you’re in luck, as the Taig 2019 CNC micro mill integrates with Mach3.

There are two models in the 2019 CNC range, the standard micro mill, and the 2019DSLS. The DSLS costs $2,995, an extra $500, but for your money, you get twice the traverse speeds (60 inches per minute) thanks to the advanced digital sync lock servo control.

It also upgrades to a closed-loop system for better error correction and regulation. Both come as a kit and so this DIY aluminum mill assembling, but for the price both represent great value for money as low-cost metal CNC mills. Overall, it’s an effective low-cost option for desktop CNC milling aluminum, and a good steel CNC machine.

5. MillRight CNC Power Route XL – Large CNC Metal Machine with High Torque

- Price: $5,359

- Work Area: 49.5” x 49.5” x 5”

- Material Compatibility: Aluminum and other software metals, wood, plastic, foam, carbon fiber, and circuit boards

Pros

Designed for hobbyists and small business use.

Large work area.

Can cut a wide range of materials.

Cons

Pretty expensive and difficult to find.

While most the CNC routers on this list are DIY desktop machines designed for use by hobbyists and small businesses, the MillRight Power Route XL is a different beast. This is a large, powerful CNC metal machine designed for use in industrial settings.

This CNC mill is 69” wide, 66” deep, 49” high, and weighs around 450 pounds. It has a working area of 49.5” x 49.5” x 5”, which is considerably larger than desktop routers and means it can be used for a much wider range of projects.

As well as aluminum and other software metals, the Power Route XL can cut wood, plastic, foam, carbon fiber, and circuit boards, so it’s a really versatile machine. It can even make occasional light cuts in hard metals.

This is by far MillRight’s largest and most precise machine, with material removal rates of up to 15 times higher than its other machines.

It’s also an incredibly robust CNC mill, due to its heavy-duty construction. In addition to its high precision, it has a high drive torque system for incredibly cutting power.

The Power Route XL comes pre-assembled, which each machine also tested before shipping to ensure it works. MillRight provides free technical support with each purchase, and there is also an active user forum where you can discuss the machine with other users.

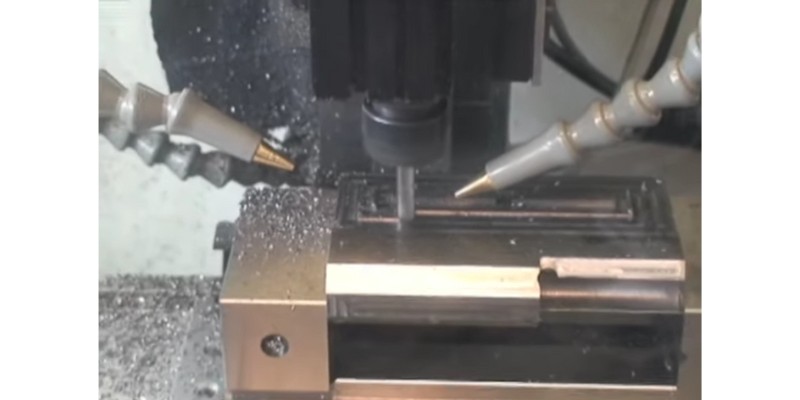

6. Tormach PCNC 440 entry package

- Price: $6,490+

- Work Area: 10” x 6.25” x 10”

- Max Spindle Speed: 10,000 RPM

- Material Compatibility: Aluminum, but tougher metals like steel and titanium — as well as standard PCB boards, plastics, and woods.

Pros

High quality with precise and accurate cuts.

Powerful enough to comfortably mill metals like aluminum, steel, and titanium.

Tormach have also developed their own intuitive CNC controller software, PathPilot.

Cons

Pretty expensive for an entry-level package.

Tormach’s entry-level mini metal CNC mill takes your metal cutting creativity to the next level compared with CNC routers. The extra torque means not only can you work with aluminum, but tougher metals like steel and titanium — as well as standard PCB boards, plastics, and woods.

The price quoted above is for their Entry Package, but for an extra few thousand dollars you can add on the mill stand, chip tray, and tooling, that by default the entry package doesn’t come with.

It’s high quality, with a cast iron frame and table that anchor the metal CNC mill down and negate vibrations, keeping your cuts precise for accurate parts without defects. All three axes use ball screws to further aid precision.

The 10,000 RPM, R8 spindle is powerful enough to comfortably mill metals like aluminum, steel, and titanium. You can also customize the Tormach PCNC 440 with accessories like an enclosure kit to keep your project’s chips and dust in, a power drawbar, flood coolant kit, and automatic tool changer.

Tormach have also developed their own intuitive CNC controller software, PathPilot. PathPilot lets you tweak g-code as you go, and is designed to be easy to learn. In addition, there’s plenty of well-designed resources to learn within the PathPilot Hub online.

If you really want to cut and mill aluminum and tougher parts seriously, consider stepping up into the CNC benchtop metal mill game rather than a CNC router.

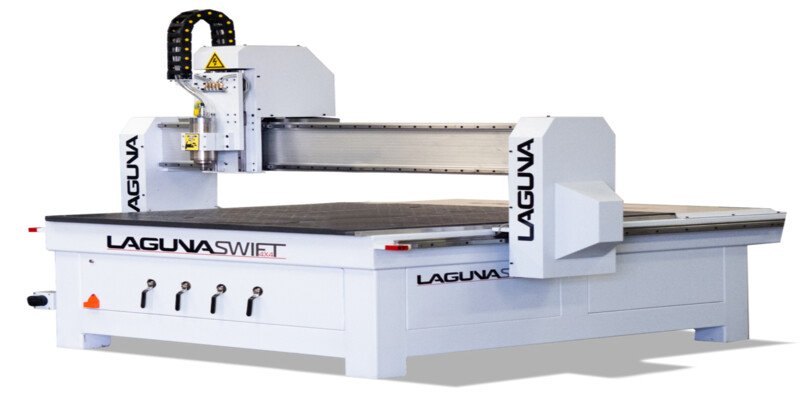

7. Laguna Swift 4×8 – Great Industrial Metal CNC Router

- Price: $13,645

- Work Area:4×8 foot

- Max Spindle Speed: 24,000 RPM

- Material Compatibility: Leather, rubber, aluminum, foam, acrylic, cardboard, wood, gaskets, and carpet

Pros

Large and high-quality.

Great for an industrial setting.

Great features make it a popular option.

Robust and sturdy.

Cons

Very expensive, and only recommended for people in an industrial setting.

The Laguna brand is well known in the CNC world for its high-quality machines, and the Swift 4×8 is perfect if you’re looking for a large router to use in an industrial setting.

Whereas most of the other machines we’ve reviewed in this guide are desktop routers, meaning they’re suited for small-scale projects, the Laguna Swift is a 4×8 router that offers a much larger working area for cutting aluminum. It’s one of the best full size CNC routers for cutting full sheets.

This metal CNC router has some really great features that make it a popular option. For example, it has 7.5” gantry clearance, so you can use it for a huge range of different projects. There’s a welded all-steel frame securing the gantry to ensure extremely high-quality cuts.

The Laguna Swift is very robust and sturdy, as the table features MDF pads and T-slots that securely hold your working materials. At the same time, it uses the same motion control as larger CNC metal machines, providing excellent edge finishes.

Another bonus is that the 3 horse-power spindle is liquid-cooled, so the metal CNC machine for aluminum can withstand long hours in demanding working environments.

If you’re new to working with this kind of CNC metal engraving machine, the Laguna website has a blog and videos you can use to develop your knowledge. The Swift also comes with a hand-held controller that makes it easy to use.

Tips for CNC Machining Aluminum with a CNC Router

Use lubrication

There are debates over what you should use for lubrication, and your own experimentation will inform your favorite, but generally, unless you want to break your router, make sure it stays lubricated. Mist coolant sprays with compressed air and oil work well, or cutting wax.

Use carbide endmills — either 3 flute or 2 flute

Smaller tools will suit your less powerful CNC router better. Pick a tool with decent chip clearance, a smoother surface finish, and a cutter that won’t gum up during the job with a solid helix angle — usually 35, 40, or 45 degrees. Ideally use a 3-flute carbide endmill, offering great chip clearance and strength, though 2 flutes can also work.

Use a smaller endmill

Generally, you want to use a smaller endmill with a CNC router for aluminum. Consider a 1/4” or smaller endmill, with a rigid enough cutter to prevent deflection.

Metal CNC Spindle

You’ll need a powerful enough spindle to maintain good cutting speeds and RPM while cutting aluminum, and for even tougher metals like steel. Also, for hobbyists cutting aluminum on desktop CNC routers, make sure your spindle accepts small enough collets to hold smaller cutters.

Rigidity

The move up from acrylic sheets or wood to aluminum requires exponentially more rigidity and torque. Though CNC routers aren’t nearly as rigid as even benchtop metal CNC mills, you can support your machine by using a longer, stubby tool, and a smaller depth of cut per pass.

Your metal CNC router’s rigidity determines the level of stress and vibration it can support, affecting your final part’s quality. The weight negates vibrations and can support faster feed rates.

Consider what upgrades or accessories you need

Enclosures are highly, highly recommended to prevent metal chips and dust from flying off, as is lubrication. Owners of CNC routers for aluminum may also consider generally upgrading the spindle, servos, and other parts. Beyond this, more advanced metal CNC mills can consider tool changers, power drawbars, and chip trays.

You may even consider a standard benchtop mini mill rather than a CNC machine. You can read our guide to the best mini mills for metal.

How large a table size and travel area do you need for CNC cutting metal?

If you’re only planning on cutting metal with your CNC machine, then you probably don’t need to worry too much about work areas, as metal pieces are generally small — hence benchtop metal CNC mills have smaller travel distances.

However, if you want to use your CNC router with wood, plastic, and other materials to make large projects like signs, then think about a larger machine to tackle both applications.

Unless you’re cutting really thick metal (which might be wishful thinking with a desktop CNC router anyway) the X- and Y-axes are the important specs to look at, rather than the Z-axis.

CNC Machining Aluminum: A Short Guide

Characteristics of aluminum

- Excellent machinability

- Low weight and high strength

- Corrosion and heat resistance

- Low-cost material

Types of CNC machinable aluminum

Aluminum 6061 and 7075 are two commonly used alloys, with aluminum 7075 generally better for tensile strength (83 kpsi vs 45 kpsi) and hardness (86 HRB vs 60 HRB), but offering less elongation. There are also aluminum 2011, 2024, 5052, 6063.

Aluminum is often anodized to finish it, augmenting its corrosion resistance as well as giving it a generally attractive appearance.

CNC Machining Steel: A Short Guide

Both stainless steel and steel are routinely used with CNC mills. However, CNC routers struggle. The gantry-style system in CNC routers will really struggle to cut into steel, they lack the rigidity and torque — basically, it would be really difficult.

For CNC cutting steel, opt for a desktop CNC mill steel machine like the Tormach we recommend, or Taig Micro Mill for steel. These cast-iron mills are stiff and rigid enough to cut steel without vibrating and deflecting, which with a less rigid CNC router will likely ruin your project or snap your endmill.

You also have other options like metal laser cutters, plasma cutters, and waterjet cutters.

Metal CNC applications

- Control panels

- 2D and 3D metal part fabrication

- Full 3D milling (with 5 axis machines) for prototype, model and mold creation

- Aerospace and automotive components such as brackets, housings and spline shafts

- Computer electronics parts, such as panels, enclosures, housings, consoles and more

- Industrial parts like fixtures and calipers

- Medical devices for orthopedic, endoscopic, spinal, trauma and surgical uses

How much does a metal CNC router for aluminum cost?

Low-cost desktop CNC routers for aluminum can start at under $200 for 3018 CNC routers like the Sainsmart Genmitsu 3018 Pro. However, you’ll need to use careful settings, strongly consider upgrading the spindle, stepper motors, and toolhead for a better experience.

For a better aluminum CNC router experience, use a more advanced CNC router such as the X-Carve or Shapeoko in the $2,000 range. These more heavy-duty routers can more effectively cut into soft metals like aluminum.

For cutting aluminum quicker, and for milling titanium, stainless steel and other metals, you’re better off upgrading to a mini CNC mill for metal, such as the Taig or Tormach models we mention.

However, don’t think just of your metal CNC machine’s nominal cost, but think instead about what you need, and what benefits it can bring you. For example, if you intend to set up a business and make money from your CNC router with metal parts, then you are much better off investing in a more industrial CNC machine that can make parts quickly and machine tougher materials more effectively.

Or, if you want a metal CNC machine for the occasional hobbyist use, and mostly want to create fun acrylic or wood models, then stick with a router without all the fancy extras or advanced tools a more expensive industrial machine comes with.