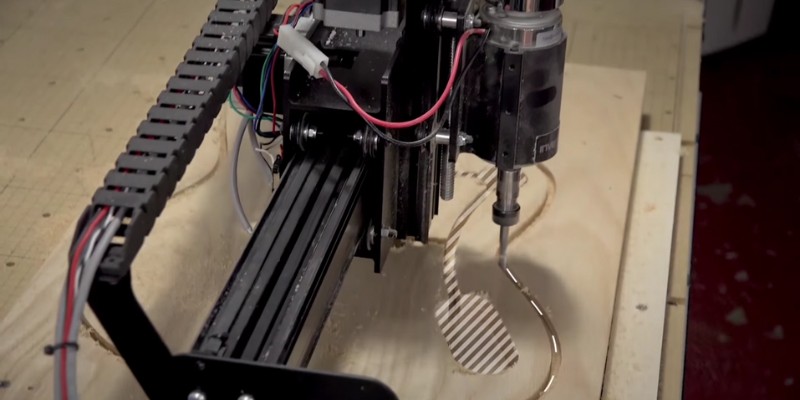

Ever dreamt of building your own guitar? Sure, you could make one by hand, but using a CNC machine will make the process much faster, easier, and – most importantly – more precise.

In this article, I’ll compare and review the best CNCs for guitar making in each price range, as well as linking to example CNC guitar projects that have been made with each CNC, and example YouTube videos.

Quick Overview

- Maslow CNC: Cheapest 4×8 CNC For Guitar Making

- MakerMade M2: Affordable 4×8 CNC with Laser Upgrade

- BobsCNC Quantum Max: Best Beginner CNC Machine for Guitar Making

- Shapeoko Pro XXL: Powerful Mid-Range CNC

- X-Carve Pro 4×4: Overall Best & Fastest Router

The Best CNCs For Guitar Making

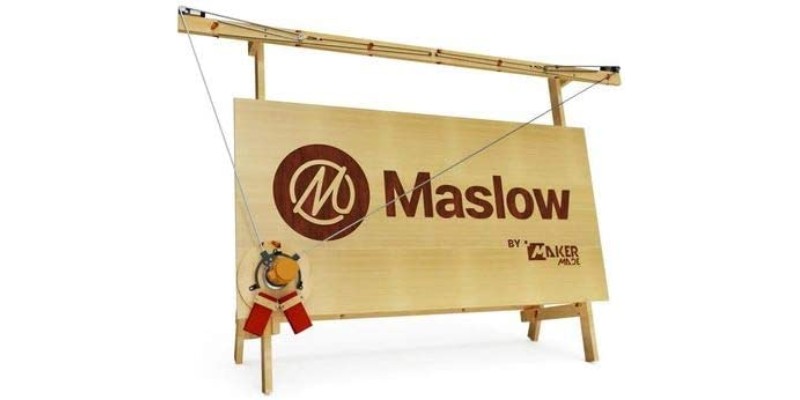

1. Maslow CNC – Cheapest 4×8 CNC Machine for Guitar Making

- Price: Check latest price at MakerMade here / Amazon here

- Cutting area: 4ft x 8ft

- Maximum Cutting Speed: 40 in/min

Pros

Large 4ft x 8ft working area for an affordable price

Completely open source

Users have created fully functional guitars

Strong community for support

Upgradeable and customizable

Cons

Time-consuming to build

The Maslow is a unique machine – an open-source large-format CNC available more affordable than any other 4×8 machine.

4ft by 8ft CNCs are typically very expensive if buying from a commercial retailer, but you can get a full Maslow kit for around $500, which is excellent value.

Because making a guitar with a CNC router involves processing some fairly large wood sheets, this larger working area makes the overall job easier and more efficient. This makes the Maslow the go-to choice for some guitar makers.

For example, Tim Sway, a popular Youtuber who creates DIY musical instruments, used the Maslow to create an electric guitar from scratch. Another user has showcased their guitar-making process in-depth on the Maslow forum.

It’s not just the fact that Maslow is the cheapest CNC machine for guitar making that makes it stand out, but also its build. It’s different from a typical tabletop CNC router, with an upright frame and the tool positioned within a sled, which is suspended on a chain system.

This construction and chain system helps keep the price low, but bear in mind it also means it takes time and work to assemble, as you need to build a frame yourself. Instructions on building a frame are included in the Maslow assembly guide.

It also means that the Maslow doesn’t offer the same level of speed, power, or precision as more expensive machines. I need to emphasize the last point: it is far less precise than more sturdy CNCs like the Shapeoko or X-Carve or Nomad 3 – but it’s much larger, and much cheaper.

You can still make fully functional guitars with it, as shown by Tim Sway and others, but it’ll take longer than other machines, and require more care when selecting your tools and settings.

As the Maslow CNC is open source, you build it yourself, rather than buying it pre-assembled The full documentation for all the parts and electronics is on the Maslow Github, and there are also build files for accessories and upgrades created by users on the Community Garden.

This CNC router uses Maslow’s own Makerverse software, an open-source CNC control program that’s designed for beginners. You can use any CAD/CAM program you like for design and g-code conversion, but Makerverse is the best control option as it’s specifically built for the Maslow.

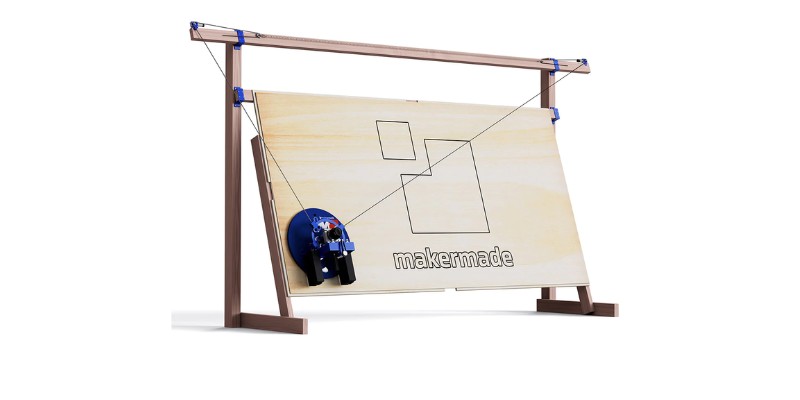

2. MakerMade M2 – Affordable 4×8 CNC with Laser Upgrade

- Price: Check latest price at MakerMade here / Amazon here

- Cutting area: 4ft x 8ft

- Cutting Speed: 40 in/min

Pros

More speed and power than the Maslow

Improved precision

Still very affordable for a 4×8 CNC

Can add a laser module

Used by popular guitar maker

Cons

Not as easy to use as other CNCs

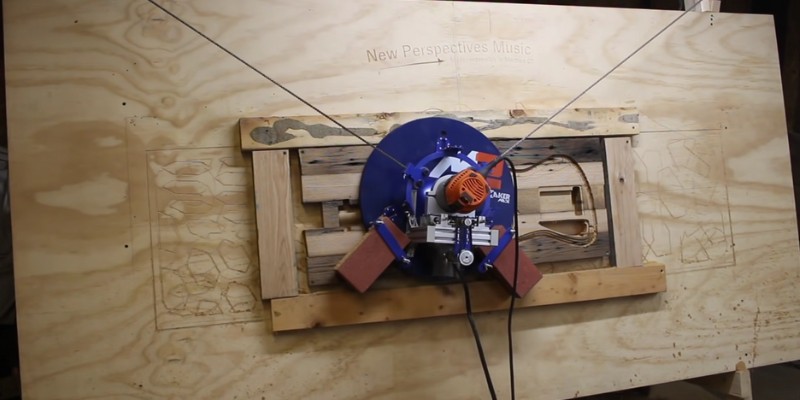

The MakerMade M2 is effectively the upgraded version of the Maslow CNC. However, the M2 isn’t open-source like its predecessor.

It’s also more expensive, but in return, you get considerably stronger performance. For starters, the M2 uses an upgraded DUE board (based on GRBL) that allows you to cut around 40% faster than with a Maslow. It improves accuracy, and simplifies the calibration process, propelling the MakerMade to be one of the best cheap 4×8 CNC routers around.

Another upgrade is the Z-axis, made from aluminum and steel, rather than the wooden sled used in the Maslow. This provides greater stability, control, and speed, while the bit has also been changed from 1/4” to 1/8” for greater precision. One similarity that remains is that the M2 is still operated using Makerverse software.

The M2 has also been proven to be a top CNC machine for guitars by Tim Sway, who provides an in-depth tutorial on 3D carving a guitar with an M2, complete with a fingerboard.

Not only that, but Tim also used the M2 to cut and laser etch a guitar stand, which brings us to another of the machine’s benefits – that you can add a laser module. This 2.8W laser is made by JTech Photonics and costs $499.99, greatly expanding your M2’s capabilities by precisely etching and engraving various materials.

While there are other large CNC routers out there, non-industrial laser engravers are typically much, much smaller than 4ft x 8ft. So, the M2 can provide both large-format CNC routing and laser engraving at a fraction of the price you’d expect to pay elsewhere.

Bear in mind that neither the Maslow nor M2 comes with a router tool included, but MakerMade offers its own branded router and others on its website.

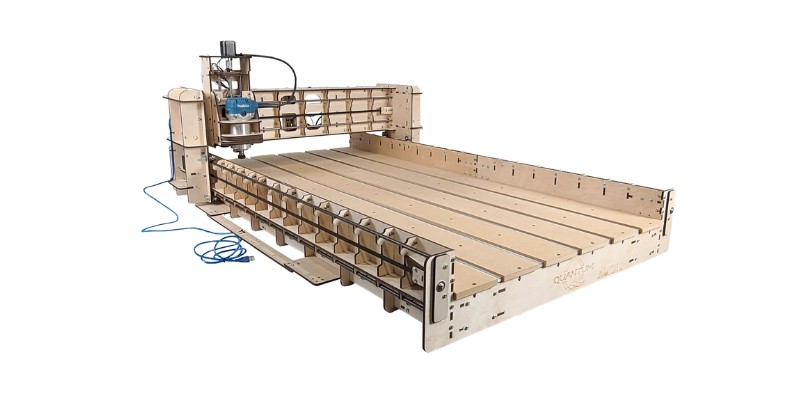

3. BobsCNC Quantum Max – Best Beginner CNC Machine for Guitar Making

- Price: Check latest price at Amazon here

- Cutting area: 50.5” x 24” x 22”

- Cutting Speed: Around 200 in/min

Pros

Large tabletop CNC router

Affordable price

Large user community

Reliable and popular brand with great support

Has been used to make guitars

Makita router included

Cons

Wood frame is less stable than metal ones

The BobsCNC Quantum Max is the largest in its Quantum series, which has replaced the brand’s popular Evolution range that was recently discontinued.

This machine is smaller than the Maslow and M2, but it’s also a lot easier to set up and use due to it being a traditional tabletop CNC router. It still provides a large enough working area for guitar fabrication.

While we couldn’t find any examples of the Quantum Max being used to make guitars, BobsCNC users have done so with the Evolution Series, and the Quantum range are essentially upgraded versions of the Evos.

BobsCNC machines are well known in the space due to their most unique feature – the fact that their frames are made completely from wood.

There are pros and cons to this.

The main benefit is that it keeps the cost low. Similar to the Maslow and M2, the Quantum Max is very cheap in comparison to other similar-sized CNC routers. BobsCNC machines are widely regarded as some of the best wood CNC machines, due to their impressive rigidity and cutting capabilities.

On the other hand, a wooden frame will never provide the same stability and rigidity as a metal one. The BobsCNC frames are well made, and has a repeatability of 0.002” to 0.004”, which is decent for the price, but you’ll still get better results from quality metal frame routers (as you’ll see below).

It also uses a belt drive on the X and Y axis, which doesn’t provide as much rigidity and smooth motion as the leadscrews and ballscrews used in more expensive machines.

BobsCNC does offer its own free software – Basic CAM and Basic Sender – but, as the names suggest, these are basic and are not really suitable for projects like guitar making. So you’re best off using third-party CNC software.

A nice aspect of using a BobsCNC machine is that there’s a fairly large and active user community, with social groups and customer design files that you can download and use for free.

You get a Makita RT0701C router tool included with the Quantum Max, which is a popular tool and is a nice addition – especially seeing as some kits like the Maslow and M2 don’t come with a router.

Overall, the Quantum Max is a solid choice if you’re looking for a large-format tabletop CNC router at an affordable price, and we think its mix of affordability, usability, and quality makes it a good option for beginners.

The Evolution series of machines, which stand out for their laser-cut wooden frames and somewhat unusual designs, with the Evo 4 being the best in the line, are possibly the most well-known products from BobsCNC.

4. Shapeoko Pro XXL – Powerful Mid-Range CNC Used by Many Guitar Makers

- Price: Check latest price at Matterhackers here

- Cutting area: 33”x33”x4”

- Cutting Speed: Around 100 in/min

Pros

Used by professional guitar makers

Comes with complete software package

Powerful and durable enough for commercial work

Very stable with high quality components

Comes with BitSetter included

Cons

Router tool sold separately

Cardibe 3D’s Shapeoko range includes some of the most popular hobbyist routers, with the Shapeoko Pro XXL being one of its biggest models.

Its large working area, while not matching those 4×8 models, is still large enough to cut two guitar bodies at once. In fact, YouTuber Mark Guitierrez used it to make one of the most stunning electric guitars we’ve ever come across that’s made with a CNC machine.

In fact, users also recommended Shapeokos for commercial guitar making, and Bryan of B Custom Guitars uses the Shapeoko Pro to make beautiful electric guitars. Bryna uses Carbide’s own Carbide Create CAD/CAM software to create his designs, and Carbide Control to operate his machine.

As the name suggests, unlike the other hobbyist Shapeokos, this model is designed as a CNC for small businesses and it uses high-quality components to provide professional quality. These include wide and stiff 15mm belts, a leadscrew-driven Z-axis with heavy-duty linear bearings, and precision-machined aluminum end plates for high precision.

We also like the hybrid integrated T-slot and MFD table, which not only provides great rigidity, but also simplifies work holding. This is because the T-slots and MDF slats provide various work-holding options, such as the ability to hold stock to the MDF with tape or glue or attach a vase or threaded table to the T-slots.

Another nice feature is that the Shapeoko Pro XXL comes with a Carbide 3D BitSetter included. This is an automatic offset probe that measures the length of the bit in your spindle and resets the Z-axis point accordingly. This makes tool changes much more straightforward, and lets you use multiple tools in a job without needing to stop and re-zero manually.

If you’re looking for an even bigger and better CNC machine for guitar bodies, Shapeoko recently introduced the 5 Pro. It’s a fair bit more expensive at $3,750, but it’s available in three sizes – 2ft x 2ft, 4ft x 2ft, and 4ft x 4ft.

On the flip side, if you’re looking to save some cash, users have also made guitars with the Shapeoko 4 XL, which has a smaller working area of 33” x 17.5”, and even the Shapeoko 3. So, thanks to Shapeoko’s popularity and wide community, there are numerous proven guitar-making CNCs to pick from depending on your budget, workspace, and preferences.

One of the most well-made CNC routers, ideal for cutting tougher woods and metals like aluminum.

5. X-Carve Pro 4×4 – Overall Best & Fastest Router for Guitar Making Professionals

- Price: Check latest price at MatterHackers here

- Cutting area: 4ft x 4ft

- Cutting Speed: Around 150 in/min

Pros

Extremely high quality 4×4 CNC router

Used by professional guitar maker Highline Guitars

Powerful spindle included

Accurate down to 0.001”

Comes with excellent software

Dust vacuum and collector included in package

Cons

Very expensive

The X-Carve Pro by is the super-sized version of Inventables’ popular desktop CNC router. This is the closest to the Maslow and M2 in terms of size (Inventables don’t sell a 4×8 version), and really shows how cheap these two machines are when you look at the X-Carve’s price.

However, that’s not to say the X-Carve Pro is bad value – far from it. For the extra money, you get an incredibly sturdy and powerful machine that’s easier to assemble and operate, and more accurate.

It can also process 4ft x 8 ft sheets, so you get plenty of working area for guitar making. Alternatively, if you want to save some space and cash, it’s available with a smaller 4ft x 2ft CNC cutting area.

The construction is really impressive, with a rigid aluminum gantry, 25mm ball screws, and linear guide rails, which combine to provide an incredible cutting accuracy of 0.001” – more precise than the other machines we’ve reviewed.

This CNC router has an integrated 1.5kW (2HP) spindle with preprogrammed variable frequency drive, and an ER16 collet that supports a wide variety of different bits. For reference, the popular Makita RT0701C router you get with the Quantum Max is 1.25 HP power, so the X-Carve Pro’s is significantly more powerful. This lets you cut deeper and faster in a single pass.

Another impressive feature is the innovative dust shoe, designed to support fast bit changes and deep spindle plunges while providing efficient suction to rapidly clear debris from your workpiece.

Not only that, but the X-Carve Pro kit comes with a Fein Vacuum and Dust Deputy (together worth $555), included, for keeping your workpiece both clean and safe without having to splash out on a separate setup.

It’s because of all these features that the X-Carve Pro is one of the best examples of CNC for guitar building. For example, custom guitar maker Highline Guitars has a video series (totaling over four hours) covering every step used to make the body, neck, and fretboard.

In a separate video, Chris Monck of Highline Guitars explains how the X-Carve Pro and Easel, Inventables’ CNC software. Chris explains that the machine’s power allows him to cut twice as fast as with his old CNC, while Easel’s extremely intuitive design ecosystem reduces the usual learning curve and makes the overall design process quick and easy.

Another X-Carve Pro user, Steve Carmichael, has also made an electric guitar with this router, while another made a Les Paul guitar using it.

While the X-Carve Pro’s price puts it out of range for most beginners and casual hobbyists, its combination of power, speed, and precision, along with its large size and intuitive software, make it perfect for experienced CNCers and professional guitar makers.

What to Consider When Buying a CNC Machine for Guitar Making

Price

The price of CNC routers varies widely, from under $500 for a Maslow to close to $10,000 for an X-Carve Pro 4×4.

The main factors that affect a CNC machine’s price are its power, speed, accuracy, build quality, usability, and software quality. So, while you can make a CNC guitar on a budget, it’s important to understand the limitations of more affordable machines.

For example, the Maslow CNC is designed specifically as an affordable option. It has a large format CNC platform at an incredibly low price, but isn’t straightforward to assemble or operate, is made of wood, comes with fairly basic software, and doesn’t offer the same quality in terms of speed, precision, and rigidity as other machines.

On the flip side, the X-Carve is very expensive but is precise down to 0.001”, has an incredibly stable metal frame with top-quality components, and comes with a powerful spindle.

| CNC | Price |

|---|---|

| Maslow CNC | $549 |

| MakerMade M2 | $1198 |

| BobsCNC Quantum Max | $1280 |

| Shapeoko Pro XXL | $1970 |

| X-Carve Pro 4×4 | $10475 |

Speed

Making a guitar from scratch can take time, and while beginners and casual hobbyists may opt for slower machines to save cash, speed is a priority if you’re looking to use your CNC commercially.

However, speed is also dependent on many factors, including the material and bit you’re using, as well as your settings. However, higher-quality components offer more speed options.

For example, the M2 is 40% faster than the Maslow, in part because it uses a more stable metal Z-axis, rather than a wooden one. Similarly, the X-Carve Pro is faster than the other machines we’ve reviewed because it uses the most powerful spindle, ballscrews for smooth motion, and large 292 oz-in NEMA 23 stepper motors.

| CNC | Cutting Speed |

|---|---|

| Laser | Cutting Area |

| Maslow CNC | 40 in/min |

| MakerMade M2 | 40 in/min |

| BobsCNC Quantum Max | Around 200 in/min |

| Shapeoko Pro XXL | Around 100 in/min |

| X-Carve Pro 4×4 | Around 150 in/min |

Power

Your spindle’s HP primarily determines power. Power impacts speed and cutting depth – a more powerful router can cut deeper in a single pass than a less powerful one.

For example, the BobsCNC Quantum Max comes with a Makita RT0701C included, which has 1.25 HP. Many CNC machine kits, including the Maslow, M2, and Shapeoko Pro, don’t come with routers, so you need to buy one separately depending on your preferences.

MakerMade’s own CNC router has 1 HP, as does the Bosch Colt PR20EVS they sell. Carbide also offers its own Carbide Compact Router, which has a max HP of 0.85.

While these are more than capable of doing a job, they don’t offer the same power as the X-Carve Pro’s 2 HP router, which provides much more efficient cutting for professionals and business owners.

Accuracy

Similar to speed, a CNC machine’s accuracy is dependent on many factors, but higher-quality builds provide more accurate cutting.

For example, the wooden BobsCNC Quantum Max has a repeatability of 0.002”-0.004”, while the X-Carve Pro is precise down to 0.001” with the right settings.

Accuracy is particularly important if you’re making a whole guitar rather than just the body, as the fretboard needs to be precisely cut and engraved to have a functional end product.

Size and Capacity

As guitars are fairly large and require you to process large sheets of wood, you need to make sure you have a CNC router that’s large enough for the job.

There’s no set size required for making a guitar, but you’ll want at least 2.5ft x 2.5ft in working area. The Shapeoko Pro XXL is 2.75ft x 2.75ft and has been used to create many guitars, but you wouldn’t want to go much smaller.

However, going for a larger model can improve efficiency – for example, the Maslow, M2, and X-Carve Pro can all cut full-size 4ft x 8ft sheets.

Not only does this give you more room to work with, but you can even carve two guitar bodies and multiple guitar components from a single workpiece with a larger CNC. If you’re unsure of the size you want to make, and want some inspiration for your next guitar project, we’ve also written an article on the coolest CNC guitar projects and files.

| CNC | Cutting Area |

|---|---|

| Maslow CNC | 4x8ft |

| MakerMade M2 | 4x8ft |

| BobsCNC Quantum Max | 50.5” x 24” x 22” |

| Shapeoko Pro XXL | 33”x33”x4” |

| X-Carve Pro 4×4 | 4x4ft |

FAQs

What size CNC do I need for guitar making?

Ideally, you want a working area of at least 2.5ft x 2.5ft (30” x 30”) for CNC guitar making, although a 4ft x 4ft or 4ft x 8ft machine makes it easier by giving you more room to work with.

How long does it take to CNC a guitar?

Most experience guitar-making CNCers estimate that it takes around 5-6 hours to CNC a guitar, but it can take much longer (such as a few weeks) depending on your experience, skill level, machine ability, and setup.