Key Takeaways

Here are some takeaways for this page:

- 6 axis CNC: A 6 axis CNC machine is a type of CNC machine that can move and rotate its cutting tool or workpiece in six different directions. It can perform complex and precise operations that are impossible or difficult with conventional CNC machines.

- 6 axis CNC advantages: A 6 axis CNC machine has many advantages over other CNC machines, such as higher accuracy, faster production, less waste, more flexibility, and more creativity. It can create intricate shapes and curves, cut from multiple angles, and reduce the need for multiple setups and fixtures.

- 6 axis CNC applications: A 6 axis CNC machine can be used for various applications in different industries, such as aerospace, automotive, medical, military, and art. It can make parts and products that require high precision and quality, such as turbine blades, engine blocks, surgical implants, firearms, and sculptures.

- 6 axis CNC challenges: A 6 axis CNC machine also has some challenges and limitations, such as higher cost, complexity, maintenance, and skill requirements. It is more expensive to buy and operate than other CNC machines. It also requires more advanced software, hardware, and programming skills to operate and control.

If you’re familiar with CNC routers, you probably know they come with different numbers of axes – the most common being 3 axis routers, but with 4 axis CNC routers and 5 axis machines also widely used. However, fewer people are aware that there are also 6 axis CNC machines out there.

In this guide, we cover everything you need to know about 6 axis CNC machines. We explain what they are, how they work, and how they compare to routers with different numbers of axes. We’ll then explain what 6 axis CNC routers are used for how much they cost.

What is a 6 Axis CNC Router?

Every CNC router, mill, and lathe use axes which are essential to the manufacturing process. This is because the axes determine how both the tools and workpieces move during production.

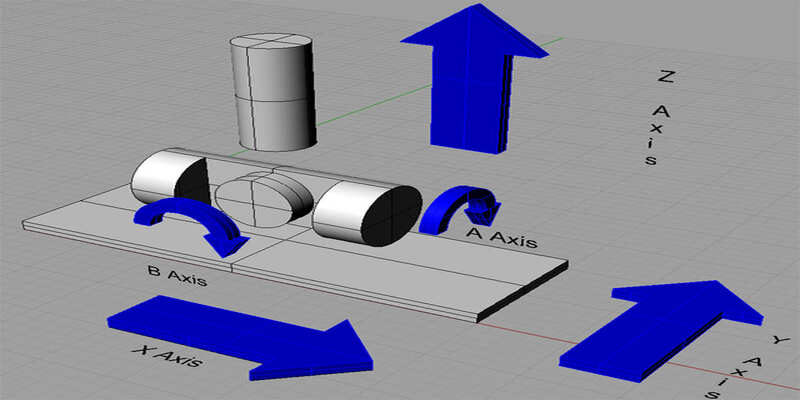

3 axis CNC machines are the simplest and have X, Y, and Z-axis which move left to right, front to back, and up and down. 4 axis machines add an additional rotational axis, but a 5 axis machine adds another one on top of that. With a 6 axis CNC, there’s – you guessed it – a third rotational axis added around the Z-axis.

To truly grasp what this means, we need to take a closer look at the effect of adding additional rotational axes on a CNC machine.

6 Axis CNC Routers vs 3, 4 & 5 Axis Machines

As we’ve just touched on, the more axes a CNC machine has, the more complex manufacturing it’s capable of.

3 axis are the most basic form of CNC machines, in which each axis is only capable of moving vertically or horizontally. These machines actually work in a similar way to 3D printers, just with a fast-moving cutting tool rather than an extruder.

This means the machines are mostly used for processing flat 2D and 2.5D parts. It is possible to work on 6 sides of a workpiece with a 3 axis machine, but it means you need to set up a new fixture for each side, which is time-consuming and can result in less precise machining.

With a 4 axis CNC, the added rotational movement around the X-axis, known as the A-axis, means the workpiece is rotated during manufacturing. Although you can configure these machines in different ways, typically the workpiece is mounted on the X-axis and therefore rotates with the A-axis.

Read more: our guide to 3, 4, and 5 axis CNC machines

The additional axis means a 4 axis CNC machine can work on four sides of a product at once, greatly increasing efficiency in comparison to 3 axis machines. As well as increasing manufacturing speeds, the rotary axis can process a wider variety of shapes, including complex helix shapes.

A 5 axis machine takes things up a gear, adding another rotational axis around the Y-axis. With a 5 axis CNC machine, both the spindle and the workpiece can rotate, producing multidimensional movement that improves efficiency, accuracy, and adds a wider variety of functions. These machines are used industrially to produce complex parts such as automotive molds and military products.

Then we get to 6 axis machines, which offer rotary axes around each of the X, Y, and Z axes. The rotational axes are known as the A, B, and C axes, respectively. This allows them to perform even more 5 axis machines, offering faster and more accurate machining of highly complex shapes. Now, let’s take a closer look at the advantages 6 axis CNC machines have over others.

Benefits of 6 Axis CNC Routers

Speed & efficiency

The main advantage of using a 6 axis CNC machine over a 5 axis one is that 6 axes significantly quicken working speeds. This is because of the additional rotary axis that means more sides of a workpiece can be processed with fewer fixtures.

In fact, according to CNC machining retailer Kingsbury, some 6 axis CNC mills can reduce manufacturing times by as much as 75%. This is a huge advantage to people working in industries with high volume production requirements.

Work on more complex shapes

Another major benefit of 6 axis CNC machines is that they can machine extremely complex parts that would be impossible or take much longer and be more difficult with 5 axis machines.

One example is the manufacturing of artificial bones for use in medical settings, which can be done with a 5 axis machine, but not with the same speed and accuracy as a 6 axis one. It’s the same story with complex structural aircraft parts.

Higher volume production

The added functionality of a 6 axis CNC machine means that companies can manufacture longer, larger parts at quicker speeds than with 5 axis CNC machines. We take a look at an example of this in action below, where a company managed to more than double the length of its parts by using a 6 axis CNC mill.

What are 6 Axis CNC Routers Used For?

As 6 axis machines offer the most advanced form of CNC machining, they’re used in industries that create highly complex and expensive parts which need to be produced en masse. Some examples include the use of 6 axis CNC machines in the production of large automotive and aerospace parts, but that only scratches the surface.

6 axis CNC machines are also widely used in model making and for creating molds for the automotive industry and others, as well as in the production of medical and military products. For example, they can be used to process airfoils for military helicopter blades and aircraft wings, as well as for weapon development. Raytheon uses a 6 axis CNC machine to develop 20-foot cruise missiles.

One example of a company that uses 6 axis CNC routers is Triumph Structures, a Kansas-based company that makes structural aircraft parts from titanium and aluminum that can measure up to 80 feet long.

Triumph Structures previously used 21 separate 5 axis CNC machines and wanted a solution that would make the overall process more efficient. Specifically, they wanted a machine that would primarily be used for machining long parts over long cutting cycles lasting several days, but that could also machine smaller parts and work on an entire machine bed at once.

The company commissioned a bespoke 6 axis CNC machine from German manufacturer Zimmerman, which took 18 months to build. Once finished, Harry Thurmond, the president of Triumph Structures, said that the machine reduced cycle times by 35%, massively improving efficiency.

It also helped them improve the accuracy of their machining. According to Thurmond, the machine allowed them to achieve better than 125 RMS on inside surfaces and 32 RMS on the outside of their aluminum structurals. RMS is a representation of surface roughness, and these figures mean that the finished product was of very high quality and extremely precise.

Finally, not only did the Zimmerman 6 axis CNC improve efficiency and accuracy, but it also opened up more possibilities. It allowed the company to expand from 22ft parts, which they were limited to when using 5 axis routers, into parts measuring 40ft to 80ft.

This is a great example of just how valuable an axis CNC machine can be to companies operating in various industries.

How Much do 6 Axis CNC Routers Cost?

Just as more axes in a CNC machine means increased flexibility and production quality, it also means less availability and more expense.

3 axis CNC routers are the most widely available and most used by hobbyists. You can easily pick up a simple yet good quality 3 axis CNC router from places like Amazon for just a few hundred dollars.

Read more: our buyer’s guide of the best cheap CNC routers

4 axis CNC routers are less common and more expensive, so you have fewer models to choose from. However, there are 4 axis CNC machines you can pick up for under $1,000, so they’re not completely out of reach of serious CNC hobbyists.

Read more: our buyer’s guide for 4 axis CNC routers

5 axis CNC routers are a lot more expensive and are mostly used in business and industry for high volume production – there aren’t really any 5 axis machines aimed at the casual or prosumer CNC enthusiast. The cheapest 5 axis CNCs start from around $3,000, with more industrial machines $30,000+.

This is also the case with 6 axis CNC machines — but even more so. They’re restricted to big industry, and have prices to match. In fact, most 6 axis CNC manufacturers don’t even display the prices of their machines, so you need to contact them to get a quote.

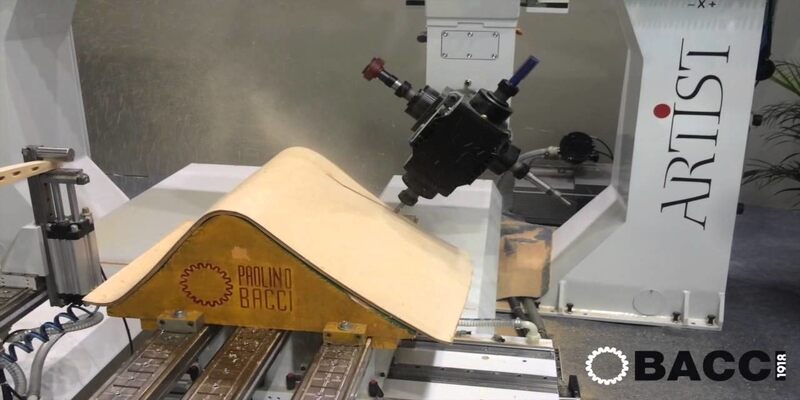

That’s not to say they’re impossible to get hold of, though. The Paulino Bacci Master 6 Axis CNC Router is one example, while DirectIndustry.com has various 6 axis milling machines available from the likes of LT Ultra, Kira America, Zimmerman, and Matec.

In truth, most people involved in CNC manufacturing – even business and industry owners – don’t need a 6 axis machine. However, if you are involved in the high volume production of complex, expensive parts, then a 6 axis CNC machine could be a great addition to your arsenal.

Conclusion

While 6 axis CNC machining is less well known and yet to be as widely used as 5 axis machining, it’s an extremely powerful tool that can provide a huge boost to companies working in certain industries.

Triumph Structures’ Zimmerman 6 axis CNC machine is just one example of how these machines can massively increase manufacturing speed, accuracy and overall efficiency, while also opening up more possibilities regarding the shape and size of manufactured parts.

We’re sure to see 6 axis machining soon become more widely used in industries like aerospace and automotive as the technology continues to evolve.