Key Takeaways

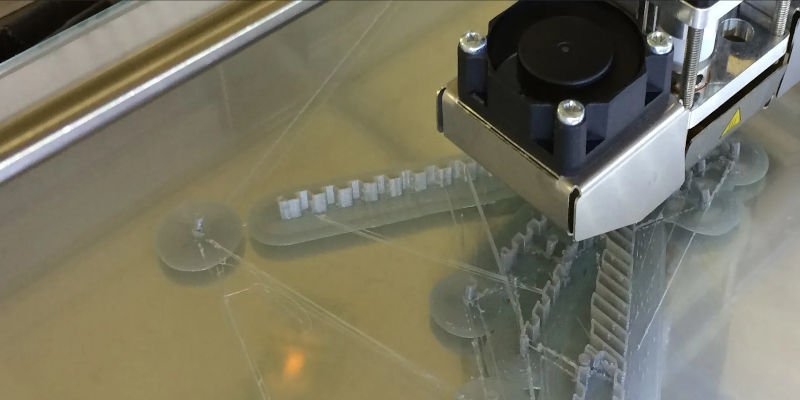

- CNC router: A CNC router is a computer-controlled cutting machine that can cut, carve, and engrave various materials such as wood, plastic, metal, and foam. It can be used to create signs, furniture, toys, molds, and more.

- Market demand: There is a growing demand for customized and personalized products that cannot be mass-produced. CNC routers can help small businesses and individuals to create unique designs and prototypes at a low cost.

- Business models: There are several business models that can be used to monetize a CNC router, such as selling products directly to customers, offering design and fabrication services, teaching classes and workshops, or licensing designs to other makers.

- Marketing strategies: To attract customers and stand out from the competition, it’s important to have a strong online presence, showcase your portfolio and testimonials, offer competitive pricing and turnaround time, and provide excellent customer service.

Which one of us hasn’t looked at a creative pursuit and wondered if there was a way to make money from it? If you write in your spare time, you’ve probably considered releasing a book or anthology. If you’re good with your hands, then maybe you’ve considered charging for repairs or original builds.

In any case, we’ve all thought about turning a hobby or skill into a job at some point. For CNC enthusiasts, the question of ‘can I make money with my CNC router?’ is a question very few can honestly admit to never asking.

If you haven’t purchased a CNC router yet and are considering one, read our CNC router buyer’s guide.

As far as the goal of starting a CNC business goes, the difficulty in setting it up and the work required depends on the scope of your ambition.

Starting up a CNC business can be as simple as finding a good project then creating and designing it, sticking to it, and selling it online. This specialty can be anything from birdhouses to furniture, and can easily be sold on popular amateur consumer sites for some quick cash.

If, however, your professional dreams go beyond some extra pocket change, you will need to know how to set up a business in CNC, where to go, who to trust, and how to make sure your time and money are used as efficiently as possible.

As a self-employed creator myself, I can tell you that it’s not easy setting up one’s own business. But despite the stress and occasional worry, it’s a rewarding and life-affirming endeavor that you can be proud of.

Here we’re going to look at how to set up a business and start making money with your CNC router, as well as some useful hints and tips to make sure your journey both starts and stays on the right foot.

Things to know before starting a CNC router business

There are several things to consider if you’re wondering how to start a CNC business, one of the main factors being the initial cost.

You can pick up small, cheap CNC routers for a few hundred dollars, but if you’re looking for a high-quality and reliable model to produce good products, expect to spend a minimum of $1,000. Our guide on how much CNC machines cost explains what features you get at each price range.

There are also additional costs to consider, such as for CNC software. While there are some free programs available, the best CAD/CAM software require paid subscriptions.

Also, bear in mind the skill level required – it takes time and patience to perfect the art of CNCing.

With that being said, there’s real potential to make side money with CNC routers, whether you’re making furniture, signs, or even musical instruments.

For example, as Andy Bird of Andy Bird Builds explains, once you have the files and cutting process for 4 or 5 products down, then turnaround times become “very quick, even for personalized products”.

That, coupled with the relatively low startup costs, makes CNC side-hustles very viable.

Making Money with a CNC Router: What Should You Make?

Making money with a CNC router is just like making money anywhere else. You can’t simply pick something you like and hope it does well. While this may be the dream, what you want to sell may not necessarily be what’s popular.

Of course, there’s nothing wrong with selling what you love to make, but it’s always a good idea to have a variety of products available to turn yourself into a one-stop-shop, so to speak. While you may be set on making one thing, here are some of the best-selling CNC products online today.

1 – Custom Signs

There’s nothing like a customized sign to help a business stand out or a home feel unique. From door hangers to shop decorations, there’s always demand for CNC signs on the market.

Wooden signs are a staple of any storefront. Regardless of the reasons for wanting one, be they personal or professional, everyone wants a sign unique to them. This makes CNC signs a very profitable route for designers and CNC router owners to go down.

If every sign is to be unique, however, you’ll want to make sure you have a decent background in design. Getting familiar with your CAD software to create signs from scratch is imperative to stand out in a marketplace with which just about anyone making money with their CNC routers is already involved.

2 – Furniture

Making furniture can be complicated, yes, but it’s a great idea for making money with a CNC router.

Simple tables and stools can be made with just a little research and a willingness to roll up your sleeves. With enough practice and patience — and a large enough CNC router — you can make large pieces like deck chairs, custom furnishings, and intricate coffee tables.

Unlike decorative items like signs and wall maps, furniture is practical and expected to take some weight. If you’re wanting to make money with CNC furniture, you’re going to want to be as sure as you can be that you know what you’re doing.

Going cheap with things like materials, tools, and wood adhesive is never a good idea when safety is on the line. If you’re going down the furniture route with your CNC business, get a lot of practice and testing under your belt and be as sure as you can be that what you’re providing is safe and secure.

For more: 20+ CNC furniture projects and ideas for inspiration

Once you’re confident that you can put together a sound table or chair, you can find your own style and make your work unique. Specific patterns or etchings act as a signature and make your work a recognizable brand instead of just another copy-paste CNC project anyone can do.

3 – Wall Art

If you’re more interested in creative rather than functional products, CNC wall art is another option. From parametric 3D pieces to cityscapes and map art, the possibilities are endless.

The great thing about making artistic CNC products is that it can be easier to differentiate yourself from the competition compared to, say, if you’re making furniture. You can experiment with different designs, colors, and materials until you find your niche, and have fun while doing so.

Because of the steadfast nature of continental shapes, these maps can be remade over and over again to whatever size specifications your customer wants. You’ll find wall maps to be a great way to make money with CNC, and a great addition to your catalog.

4 – Musical instruments

One of the more challenging but potentially lucrative CNC side hustles is making musical instruments like guitars and violins. A good example is B Custom Guitars, whose owner Bryan carves electric guitars using a Shapeoko, and there are numerous other examples on YouTube.

This is where the real selling point of CNC instruments is – the ability to make a completely unique and custom instrument according to a client’s wishes.

You can also make accessories, such as guitar wall hangers and stands, to go with your instruments.

5 – Jewelry

Another potential CNC business is jewelry making, although you’ll need a laser engraver and/or CNC mill, rather than a router, for working with metals.

The best bet is a CNC laser for jewelry, as these are cheaper than mills. There are now entry-level lasers like the xTool D1 Pro that have infrared laser accessories for engraving ferrous metals such as gold and silver.

With a CNC laser, you can run a personalized laser jewelry engraving service or even create your own products from scratch, such as laser cut copper earrings. Custom jewelry boxes are another potential idea.

6 – Cabinetry

There are companies that CNC-build entire kitchen cabinets, such as the Bruckelmyre Shop and CNCcabinetry, but there’s no reason you can’t start small by targeting your local area and gradually building up a client base.

You’ll be able to provide cheaper work than more established businesses anyway, and should still be able to turn a profit. You can use specialized cabinet making software to help you get started.

7 – Clocks

Another of the more unique options is CNC clock making, a niche which can be tricky to master, but has lower competition than others like furniture making.

In fact, this is one of the areas where you can really stand out from the competition with creative ideas, from classy personalized clocks to abstract designs and quirky creations like this Bitcoin clock.

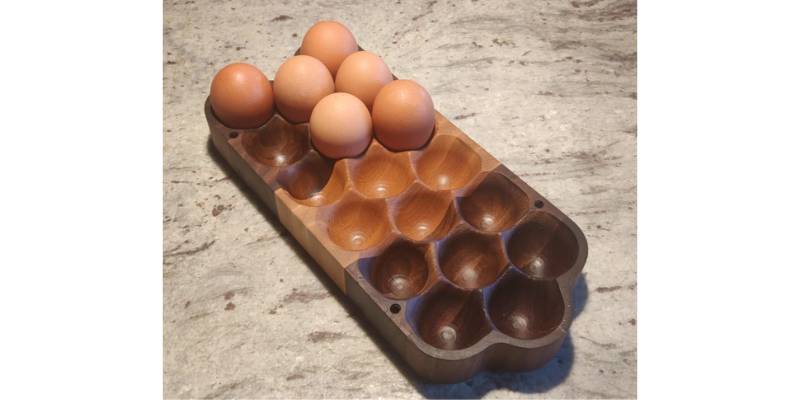

8 – Kitchenware

Instruments, clocks, wall art, and jewelry are all quite intricate CNC projects, but a potential business idea for more straightforward projects is kitchenware. This can include personalized cutting boards, wooden cutlery and bowls, coasters, and wood-mounted bottle openers.

Read more: our article on profitable CNC projects that sell

Generalize your Services

If you’re a jack- or jill-of-all-trades, then you may find joy in using your CNC router to be a general carpenter and designer for events and performances.

Theaters always need props, festivals need stands and kiosks, and town fairs will always need signs and decorations.

If you find yourself with too many ideas and skills to generalize, selling your services as the owner of a CNC machine could be the way to go!

Just a few samples of what you can do and a bit of gumption is all it should take to get your foot in the door with your business. From there, it’s just a matter of proving yourself and your skills.

How to Start a CNC Business: General Tips & Mindset

Starting any business will take some careful planning, but there are a few other key steps that may not have crossed your mind. Making money with a CNC router is pretty simple (make a thing, sell the thing) but turning your CNC machining into a full-on business can be quite taxing if you don’t think it through.

Be Sure

If you’re looking to make money with your CNC router, you’re going to need a solid plan, framework, and you need to be confident in what you’re selling. The small nicks in the chair you made for yourself may give it character to you, but a customer who’s paid you for it may not see it that way.

Any business relies on good press, especially from customers. So the best way to consistently make money with your CNC router is to perfect what you’re making before slapping a price tag on it.

Know Where to Sell Your CNC Products

The internet has made starting a small business easier than it’s ever been. Sites like Etsy and eBay give creative people the chance to profit off their talents and pastimes.

If you’d rather go local, you can show off your wares in swap meets and flea markets. While profits from these are rarely anything to write home about, you get a good chance to really show off your wares and make a name for yourself within a local community.

If you really want to branch out then it’s worth opening your own shop on any one of the many reliable online retailers available. Once you’ve taken off, then getting your own site or even a real-life store could be just over the horizon!

Don’t Put All Your Eggs in One Basket

You’ll hear a lot of talk about removing safety nets and going all in, and there are some merits to these arguments. But it’s important to know where your limits are.

Starting a new business is an exciting endeavor, and it’s easy to get swept up in the thrill. The temptation to quit your day job or invest your entire savings will be there, but having a safety net is very important.

Confidence is key in a lot of things, but you need to remember the difference between confidence and arrogance. Zeal is the lifeblood of any passion, but making money with your CNC router isn’t as cut and dry as make-thing then sell-thing, there are a lot of steps.

Excited as you may be, keep the business to a side project for extra cash for a while until you’re absolutely sure you’ve got the makings of a full-time CNC router business. There’s always going to be a certain amount of risk when setting up your own CNC business, and so having some buffers will ensure one setback doesn’t equal failure.

Get Ready to Learn

It’s nice to believe that you can just make something, sell it, and you’re done. While this is effectively the case for side hustles, if you’re looking to really start a CNC business then you’re going to need to familiarize yourself with a few extra details.

Learning how to effectively promote and market yourself is key. This can be done online, through flyers, or via online stores. What you’re looking for is a good customer base that will spread through word of mouth and good online reviews.

Be sure to also research how to file your taxes if you move to full-time self-employment. If you’re in America, you’re likely already familiar with filing tax returns manually, and so will be more clued in than those of us living in Europe where taxes are mostly calculated and filed automatically.

While you don’t need a degree in business to make money with your CNC router, you will need a good grasp of the inner workings of commerce that may not have crossed your mind before. Building a business from the ground up takes more than a good product and some luck, you’ll need to make a name for yourself and make sure that name gets out there!

Be Proud of What You Make

Having faith in your products is imperative to getting your CNC business off the ground. But having pride in what you make is of the utmost importance.

The general rule of thumb is to never sell anything you wouldn’t buy yourself (were you unable to make it, that is).

Pride in your work will make it easier to produce items of consistent quality, and many customers will respond positively to independently made products that clearly have heart in them. Any job, even dream ones, can get old over time, and enthusiasm isn’t always easy to keep a hold of.

FAQs

How profitable is a CNC woodworking business?

CNC woodworking businesses can be very profitable. But, it depends on the size of your client base, your costs, your CNC machine’s capabilities, your own design and operating capabilities, and your production times.

How can I differentiate my CNC products in a saturated market?

Try entering a less competitive niche. Trying to sell products like CNC-made furniture and signs is extremely competitive, but more unique products like clocks, musical instruments, and jewelry are less saturated.

You can also look to add a new twist to products in more competitive niches, like furniture, or start off by targeting local clients with cheap services.

How do I market and sell my CNC products?

If you’re looking to sell CNC products online, sites like Etsy, Shopify, and Ebay are popular choices, as well as the likes of Gumtree and Facebook Marketplace. Creating your own brand, website, and social pages can help in marketing efforts and lead to more sales. It can also help to attend local markets and craft shows to help get your name out there and build up a local customer base.

What to read next?

- The best cheap CNC routers

- The best routers for your CNC

- Best CNC routers for small businesses to make money

- CNC controller buyer’s guide

- CNC routers vs CNC mills compared