Key Takeaways

- Wire EDM basics: A CNC machining method that uses a charged metal wire to cut conductive materials with sparks.

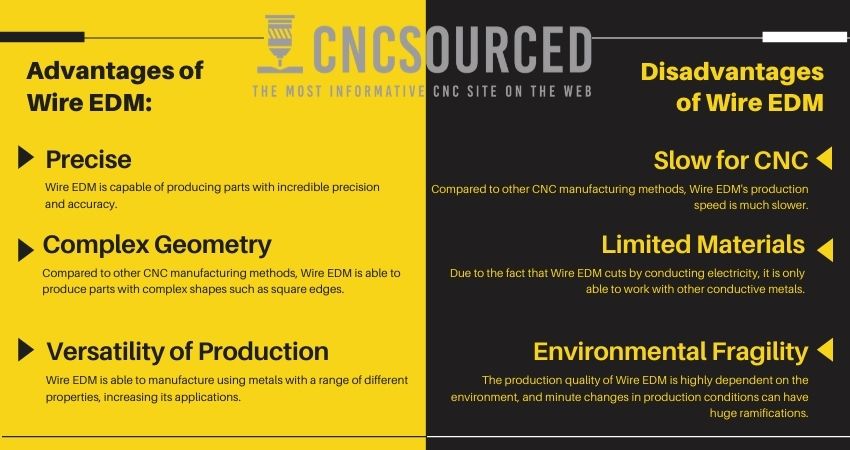

- Wire EDM advantages: Can create complex shapes, smooth finishes, and high precision. Works with various metals.

- Wire EDM disadvantages: Slow, expensive, and limited to conductive materials. Sensitive to environmental factors.

- Wire EDM applications: Used for prototyping, medical devices, military equipment, and micro-machining.

Wire EDM is a type of CNC machining technology capable of producing shapes and structures that are next to impossible with other CNC methods — and can give you incredible results.

In this guide, I’m going to step you through everything you need to have a base understanding of Wire EDM to get you started.

We’ll cover all the popular use cases, the pros and cons of different material types, as well as an overview of the costs associated with this impressive technology.

What is Wire EDM?

The theory on which Electrical Discharge Machining (EDM) is based is centuries old. Eighteenth century British Chemist Joseph Priestley observed how electrical charges had removed material from the metal electrodes in his experiments as early as 1770.

With the first functioning EDM machines being developed in the war-torn Soviet Union by physicist brothers the Lazarenkos in 1943, Wire EDM was not far behind.

EDM works by creating an electrical charge that emits sparks. These sparks are incredibly hot, between 8,000°C and 12,000°C. The heat is carefully targeted to melt away metal from a larger metal block and carefully construct the intended design.

The whole process takes place within a bath of deionized water that cools the machine — increasing the water’s resistivity. It also washes away the waste material, a process called flushing.

Wire EDM, also known as Wire-Cut EDM, works in a very similar way, using a rapidly charged conductive metal wire to melt the material. No actual contact is made between the wire and the material, which prevents distorting the path of the wire or damaging the part. Sparks jump the gap and melt away excess metal.

The wire can be highly charged in order to cut away large pieces of material. You can also reduce the machine’s voltage to engineer surface finish. At certain voltage levels, a pass of the wire can remove as little as 0.0001 inches of metal from the surface, removing the rough outer layer creating a smooth and shiny finish.

Wire EDM machines can also move along five axes, including being inclined, to create tapered effects on the metal and offering more degrees of freedom. Wire EDM machines can be rotated on these axes to create tapered indentations and very precise machined cuts.

The remarkable thing about Wire EDM technology is that using this method, it is possible to create certain geometrical features on your piece that are next to impossible with other types of CNC machine. You can create small slots, square corners, and complex shapes and designs within the metal that are impossible with, for instance, CNC milling.

Wire EDM Applications: What is Wire EDM Used For?

Prototyping

While 3D printing is often considered the foremost prototyping technology nowadays, Wire EDM is no slouch in that department. Wire EDM’s production speed makes it incredibly useful for prototyping.

CA Models, a leading prototyping company based in Stirling, Scotland, uses Wire EDM technology as a supplement to other forms of manufacturing to fulfill increasing demands for metal prototypes. Company owner and managing director, Clark Campbell, has publicly stated how, without the Wire EDM technology provided by Sodi-Tech EDM, he would be lost.

These prototypes are highly valuable as few companies offer Wire EDM prototyping. Noting the benefits of wire EDM, cutting-edge industries such as Formula 1 are beginning to use CA Models to produce rapid prototypes with extremely short turnaround times.

Medicine

Wire EDM is a particularly useful CNC technique for producing parts quickly without any contaminating materials. When producing both medical implants and molds, this is essential.

This needs to be achieved while maintaining a high production speed, as many medical devices and implants are needed in vast quantities, such as orthopedic screws and bolts, joint supports, and implanted splints.

On top of this, tools such as surgical cathodes for syringes, valves for oxygen masks and hand tools are need replacing regularly.

Companies such as California-based Milco Wire EDM are renowned for producing these items using advanced Wire EDM machines, as well as supplying for various other industries too.

Military

Another area in which Wire EDM is used is in the military. Companies like Milco Wire EDM, as well as Owens Industries Inc. are supporting the military through CNC manufacturing, specifically Wire EDM.

Every branch of the military requires a constant stream of high-quality components for both new equipment, and replacement parts for frequently used items and vehicles. Owens Industries Inc. list components for missiles, fighter jets and artillery among their main products.

Wire EDM is capable of producing the best quality parts for these uses, and each must be manufactured with the expectation that it will be used in a life and death scenario. With that in mind, quality and finish is paramount, making Wire EDM ideal.

The Pros and Cons of Wire EDM

Benefits of Wire EDM

Precise

Wire EDM has advanced to reach microscopic level cut and indentation accuracy. The technology can be programmed to make cuts mere micrometers thick.

These cuts are also highly repeatable, reducing the risk of deformation or distortion, making Wire EDM one of the most precise CNC manufacturing methods in use.

Complex Geometry

Similarly, Wire EDM can produce parts with a range of complex shapes and structures. Its five axes and therefore different cutting dimensions mean that it can produce tall, curved, straight and edged parts alike.

This vastly increases the application range of the technology and gives it uses in wide-ranging industries from medicine to high-performance transport and beyond.

Versatility of Production

Wire EDM is versatile in the hardness and conductivity of the metals it is able to cut, giving it applications in a wide array of industries.

Ranging from brass to tungsten, different materials have different compositions and are therefore more adept at producing different products. By switching out different wires, Wire EDM can create a range of finishes with the same machine.

Wire EDM Limitations

Slow for CNC

While Wire EDM is a fast production method when compared to alternative methods like 3D printing, it is not the quickest within the world of CNC.

For anything other than the smallest parts in mass quantities, other methods such as thin-wheel abrasive cutting are recommended for speed.

Limited Materials

Wire EDM’s method of cutting using the high temperatures of electrical conductivity means that it can only be used to cut materials that are themselves conductive.

It is incapable of effectively working on materials like plastic or wood that other CNC manufacturing methods can.

Environmental Fragility

Wire EDM’s effectiveness is heavily affected by the environment in which it is working. Minute changes to the composition of the wire, the workpiece, and the ionization of the cooling water will affect its ability to work.

This means that perfect conditions are paramount, and any change in these factors will cause unwanted alterations to the final result, and potentially damage the product.

What is EDM Wire Made From?

There are a wide variety of different conductive metals that are used for making EDM wire nowadays, each with their own benefits, drawbacks and applications.

| Material | Composition | Benefits |

|---|---|---|

| Brass | Copper and zinc alloy | Fast cutting |

| Coated Wire | Brass or copper with zinc or zinc oxide | Fast cutting, less breakage |

| Diffusion-Annealed Wire | 50% brass, 50% pure zinc | High tensile strength, better flushing |

| Steel Core | High-carbon steel core with brass coat | High tensile strength, fracture-resistant |

| Tungsten/Molybdenum | Tungsten or molybdenum | No risk of part pollution |

Brass

Brass is an alloy of copper and zinc, and has quickly become the most common EDM wire material in use today. Zinc has a lower melting and vaporizing point than copper, so the higher the saturation of zinc in the alloy, the faster it cuts.

However, there is a balancing act to be had with brass. When approaching 40% saturation, the zinc begins to change state, and the wire becomes incredibly brittle.

What’s more, saturate too much and you reduce threading reliability, so the wire does not feed into the machine as efficiently. Saturate too little, and you not only lose the strength, but the wire is less capable of making tapering cuts.

Coated Wire

Coated wires are made using process called electro-galvanization, where a brass or copper wire is coated in a very thin layer of pure zinc or zinc oxide. These wires cut much faster than their pure counterparts and break less often.

They are mostly recommended for fast finishing of products and give a better surface finish with greater integrity. However, they are more expensive than the pure brass or copper wires.

Diffusion-Annealed Wire

Diffusion-annealing is a way to reduce the harm of zinc oversaturation in the wires. A heavy coating of pure zinc is applied to the wire, which is then annealed in a furnace so the zinc diffuses into the mixture, resulting in a wire that is 50% brass and 50% pure zinc.

These wires have a more reliably high tensile strength compared to brass wires, and are recommended for cutting tall products faster. They also work well where poor flushing conditions are present, and waste material cannot be efficiently removed by the water, and are especially strong when cutting tool steels, aluminum and graphite.

Steel Core

Steel core wires, unsurprisingly, are made of a high-carbon steel core, coated in zinc-rich, diffusion-annealed brass. The steel provides high tensile strength and fracture resistance, while the highly conductive brass provides a high cutting speed.

Steel core wires can have tensile strengths as high as 290,000 psi, herculean compared to brass-based wires which can be as low as 54,000 psi, and are particularly useful in the manufacturing of extremely tall parts, or parts that require perfect straightness.

Tungsten or Molybdenum

Both tungsten and molybdenum wires are not widely used, but provide a number of crucial uses for the Wire EDM industry. Both are extremely strong, with tungsten being the strongest wire material around.

However, they are poor conductors and suffer from slower cutting speeds. Their high melting points also reduce flushing efficiency, which is a vital consideration for industrial Wire EDM operations.

Where they come into their own is in their applications. When brass and zinc wires cut, microscopic amounts of material are left behind on the finished product. In areas such as medicine and the military, this is unacceptable.

The strength of tungsten and molybdenum wires means that virtually no metal breaks off to pollute the part, and makes them the only choice in these sectors.

How Much Does Wire EDM Cost?

The Wire EDM production process is very costly. Alloying copper and zinc for brass and coating or diffusion-annealing takes a lot of investment in equipment, materials and energy. Even then, there is the process of turning the metal into wire.

There are too many variables affecting the price to come up with a solid number, but it is by far the biggest cost associated with the Wire EDM process.

Brass wires are the cheapest at about $1 per kilogram, whereas molybdenum wires cost upwards of $5 per kilogram.

But the amount of wire required means that these costs rack up very quickly. If you decide that Wire EDM is the best choice for you, shop around to find the best price you can.