Key Takeaways

- 3 axis CNC machines: The simplest and cheapest type. Good for cutting flat 2D and 2.5D parts.

- 4 axis CNC machines: More flexible and accurate. Can drill on sides and cylindrical surfaces.

- 5 axis CNC machines: The most advanced and expensive type. Can produce complex 3D shapes and angled features.

- Choosing a CNC machine: Depends on your project needs, budget, and desired level of detail.

When it comes to buying a CNC machine, the first and perhaps most important consideration is whether you need a 3 axis CNC router, a 4 axis CNC router, or a 5 axis CNC router?

The decision will tend to be based upon a compromise between the level of detail you’re trying to achieve and the budget you have available.

In this guide, I’ll explain all the differences between 3, 4, and 5 axis CNC machines so you can easily find the right CNC router for you.

In a nutshell:

- 3 axis: Most cost-effective for hobbyists. Good for 2D/2.5D parts.

- 4 axis: More flexible. Can drill on sides/cylindrical surfaces.

- 5 axis: Most precise, but most expensive. Suitable for complex machining and can produce detailed parts.

Let’s start by looking at each option in turn, and then we can compare their use cases side-by-side.

3 Axis CNC Machines

3 axis CNC machines are the most basic out of the three we’re looking at. This technique developed from the process of rotary filling, which uses just the X and Y-axis.

In a 3 axis CNC machine, the three axes are the X-axis, the Y-axis, and the Z-axis. The X-axis moves left to right, the Y-axis moves from front to back, and the Z-axis moves up and down. A 3 axis CNC machine can work on each axis at the same time.

These CNC machines are mostly used for cutting flat 2D and 2.5D parts. It is possible to machine all six sides of a part with a 3 axis CNC machine, but it requires a new fixturing set-up for each side, which is expensive and time consuming.

The workpiece is held flat while the axes move along and cut or mill. 3 axis CNC machining can be used for automatic/interactive operation, drilling holes, cutting sharp edges, and milling slots, and is widely used in the production of mechanical parts.

As 3 axis machines can only move up and down and side to side, the products you can make with them are somewhat limited compared to other machines.

However, complex and practical shapes can still be made with a 3 axis CNC mill, although it’s not well suited for parts that require a lot of depth and detailing. A 3 axis CNC milling machine is better suited to the manufacturing of planar milled profiles, drilling and threaded holes.

So with a 3 axis machine you can create 2D mechanical parts, but you can’t create 3D objects.

While there are industrial 3 axis machines that cost thousands, this type is also the cheapest and most accessible. There are many desktop 3 axis machines easily available to buy on Amazon for a few hundred dollars.

Here are some popular 3 axis CNC routers and mills:

- Vovigo CNC 3018 Pro

- Mostics 2 in 1 CNC 3018 Pro

- Yofuly Upgrade CNC 3018 Pro

- Vevor CNC 3018 Pro

- MakerMade M2 CNC 3 axis

4 Axis CNC Machines

A 4 axis CNC machine features the same three axes as on 3 axis machines, but it also has rotation around the X-axis. This is known as the A-axis. In 4 axis CNC router machining, the workpiece is also usually rotated. This means the machine can act as a milling machine as well as a CNC lathe.

A 4-axis CNC can be arranged in different ways, but they are most commonly set up for vertical machining. This means that the spindle rotates about the Z-axis, while the workpiece is mounted in the X-axis and can therefore rotate in fixture with the A-axis. In a single fixture setup, a 4 axis CNC router can work on four sides of a workpiece.

There are two types of 4 axes CNC machines:

- Index — In index machines, the rotation and cutting are done independently; the workpiece is rotated until in the correct precision and then cutting resumes.

- Continuous — Continuous 4 axis CNC machines are more efficient as they can cut and rotate simultaneously, allowing complex parts like the profile of cam lobes and helixes to be machined.

4 axis machining offers much greater flexibility than 3 axes. For example, it’s ideal for drilling on the side of parts or on cylindrical surfaces – something that isn’t capable with a 3-axis CNC mill.

In a single fixture setup, a 4 axis CNC router can work on four sides of a workpiece. This means it provides a more efficient way of machining parts that would require numerous fixtures if using a 3 axis CNC milling machine, reducing both cost and the time needed to machine the piece.

Also, no fixture changes mean that tighter tolerances are held between features on different sites of the workpiece. 4 axis CNC routers are thus more accurate than 3 axis CNC machines.

A 4 axis CNC mill can also be used to machine angled features — something a 3 axis CNC machine can’t. However, as there is only a single rotational axis per setup, you either need to angle all angled features around the same axis or use multiple fixtures.

Like 3 axis CNC machines, there are both low-cost hobbyist 4 axis CNC routers designed for home use as well as much more expensive industrial machines.

Below are some of the best 4 axis CNC machines:

5 Axis CNC Machine

A 5 axis CNC machine offers even greater flexibility and efficiency than 4 axis machines.

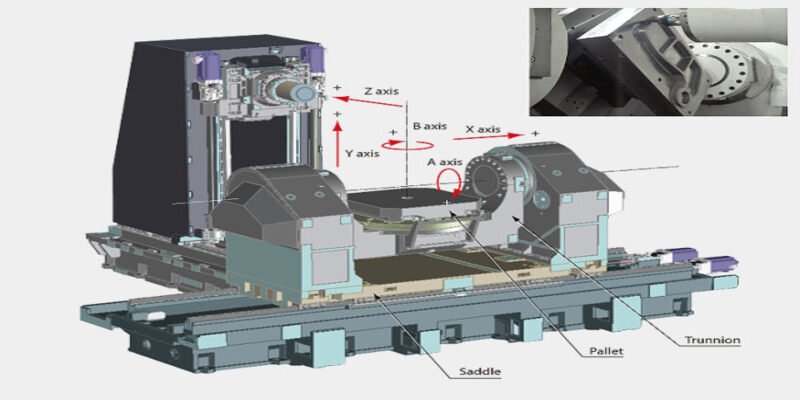

Like in 3 and 4 axis machines, the spindle and cutting tool in 5 axis machines move along the X, Y, and Z-axis. However, in a 5 axis CNC machine, there are rotations around two of the three axes. The rotation around the X-axis is called the A-axis, the rotation around the Y-axis is the B-axis, and the rotation around the Z-axis is the C axis.

5 axis machines can use any two of the rotational axes at the same time, depending on the machine’s configuration. This is either the A-axis and C-axis, or B-axis and C-axis.

In a 5 axis CNC machine, the rotation can occur by either the spindle or the workpiece. This multidimensional movement offers unparalleled accuracy and means that it can perform a wide variety of functions, including milling, turning.

Therefore, with a 5 axis CNC mill you can use a single machine for projects that would otherwise require multiple machines, as it can cut five sides of a part in one fixture. It also offers greater efficiency and improves tool life.

5 axis CNC machines are used in the production of a wide range of precise and very complex parts of things like car molds, artificial bones, military products and aerospace parts.

There are two main types of 5 axis CNC mill: 3+2 machines, and fully continuous machines.

In 3+2 axis machines, two rotational axes operate independently. This means that the workpiece can be rotated to any compound angle for the tool to machine features, but the two-axis rotation can’t be done at the same time as the machining.

In contrast, fully continuous 5 axis machines can rotate two axes simultaneously as the spindle moves the cutting tool along the X, Y and Z coordinates. Both types are able to create highly complex 3D shapes, but fully continuous machines can do so more efficiently.

These machines are the most advanced type of CNC machine and are mostly used in industrial settings. Unlike with the other two types, there aren’t really affordable 5 axis CNC machines for hobbyists.

We’ve listed some of the best 5 axis CNC machine brands below:

Difference Between 3 Axis, 4 Axis and 5 Axis CNC Machines

Now we’ve taken a look each type of CNC machine separately, here’s a quick summary of the main difference between each type:

| 3 Axis Machine | 4 Axis Machine | 5 Axis Machine | |

|---|---|---|---|

| Movement of Spindle | Up, down, side to side | Up, down, side to side, rotational | Up, down, side to side, two rotational |

| Flexibility, Accuracy and Efficiency | Standard | Better | Best |

| Applications | Mechanical parts, hobbyists | Cylindrical surfaces, 3D objects | Intricate and complex work, industrial settings |

| Cost | Cheapest | More expensive | Most expensive |

Number & movement of axis

Of course, the number of axes is the most obvious difference, and this influences the directions and movement of the spindle.

A 3 axis CNC machine moves up and down and side to side. A 4 axis CNC router has one rotational axis, while a 5 axis CNC machine has two rotational axes.

Flexibility, accuracy & efficiency

Put simply, the more axes there are, the better the machine in terms of flexibility, accuracy and efficiency.

The rotational axis of a 4 axis CNC machine gives it increased flexibility and makes it suitable for a wide range of applications. The added rotational axis and the faster rotational speed of a 5 axis machine gives even more flexibility.

Applications

Naturally, the differences between these CNC machines mean that they’re best suited for different purposes.

In businesses and industry, 3 axis CNC machines are widely used for making mechanical parts, and they’re also used for a wide range of purposes by hobbyists. A 4 axis CNC mill can do this with the added benefit of being suitable for working with cylindrical surfaces and 3D objects, while a 5 axis machine can carry out much more intricate and complex work.

Cost

As they’re the simplest form, 3 axis CNC machines are the cheapest. There are still expensive versions out there, but you can pick up a 3 axis CNC router on Amazon for a few hundred dollars.

A 4 axis CNC router is more expensive, though you can still get good machines for under a thousand dollars. 3 axis and 4 axis CNCs are best for hobbyists and small businesses.

5 axis machines on the other hand are most used in industrial settings and are much more expensive.

What CNC Machine is Best For You?

There are three main considerations you need to make when choosing between a 3, 4, and 5 axis CNC mill — what you’re using the machine for, how much accuracy you need, and your budget.

3 axis machines are best suited for casual hobbyists creating fun CNC projects, or for small home businesses machining of simple parts. They’re cheap, can be easily bought off the internet, and can be easily used to create a wide range of projects.

A 4 axis CNC router is a step up from a 3 axis CNC router in all areas. They can still be bought for a few hundred dollars, but high quality ones are more costly. They offer greater accuracy and flexibility and suit a wider range of applications. They’re best for small and mid-range businesses and serious hobbyists.

While a 5 axis CNC router offers the most advanced machining, their expensive price and more selective availability mean they’re only worth getting if you really need one. That is, if you’re producing complex and intricate parts in an industrial setting.

Conclusion

It’s very important to know the differences between a 3, 4, and 5 axis CNC milling machine before making a purchase.

3 axis machines are the most basic with a spindle that moves up and down from side to side. 4 axis machines add a rotating axis, offering greater efficiency and flexibility. 5 axis CNC machines add a second rotating axis, offering the most accurate, efficient and flexible machining.

What machine is right for you depends on your preferences. 3 axis machines are the cheapest and are best for hobbyists and small businesses. 4 axis machines can be used for more complex projects but are more expensive, while 5 axis machines are mostly used in industrial settings and cost tens of thousands of pounds.